SANTA CLARA, CA ― March 2020 ― Absolute EMS, Inc., a leading provider of turnkey and consignment manufacturing services, is pleased to announce that it has installed two new MIRTEC machines at their facility: an MV-6 OMNI 3D AOI Machine and an MS-11e 3D SPI Machine.

Absolute EMS is a leader in end-to-end electronic manufacturing services that help its customers rapidly introduce innovative new technology by facilitating speed-to-market in their marketplace. Speed-to-market starts with engineering services, and extends into prototypes, pilots and then into production.

“When Absolute EMS decided to enhance our vision systems, MIRTEC SPI and AOI equipment was the only choice,” said Doug Dow, Chief Operating Officer. “MIRTEC offers excellent optical technology, and their 15 Mega Pixel system cameras eliminate blind spots. Our customers products are highly sophisticated with micro technology, and we need the best the industry has to offer. MIRTEC offers leading-edge technology that is scalable and repeatable. I think it’s safe to say their solution exceeds competitor’s capabilities. We are very satisfied with our decision.”

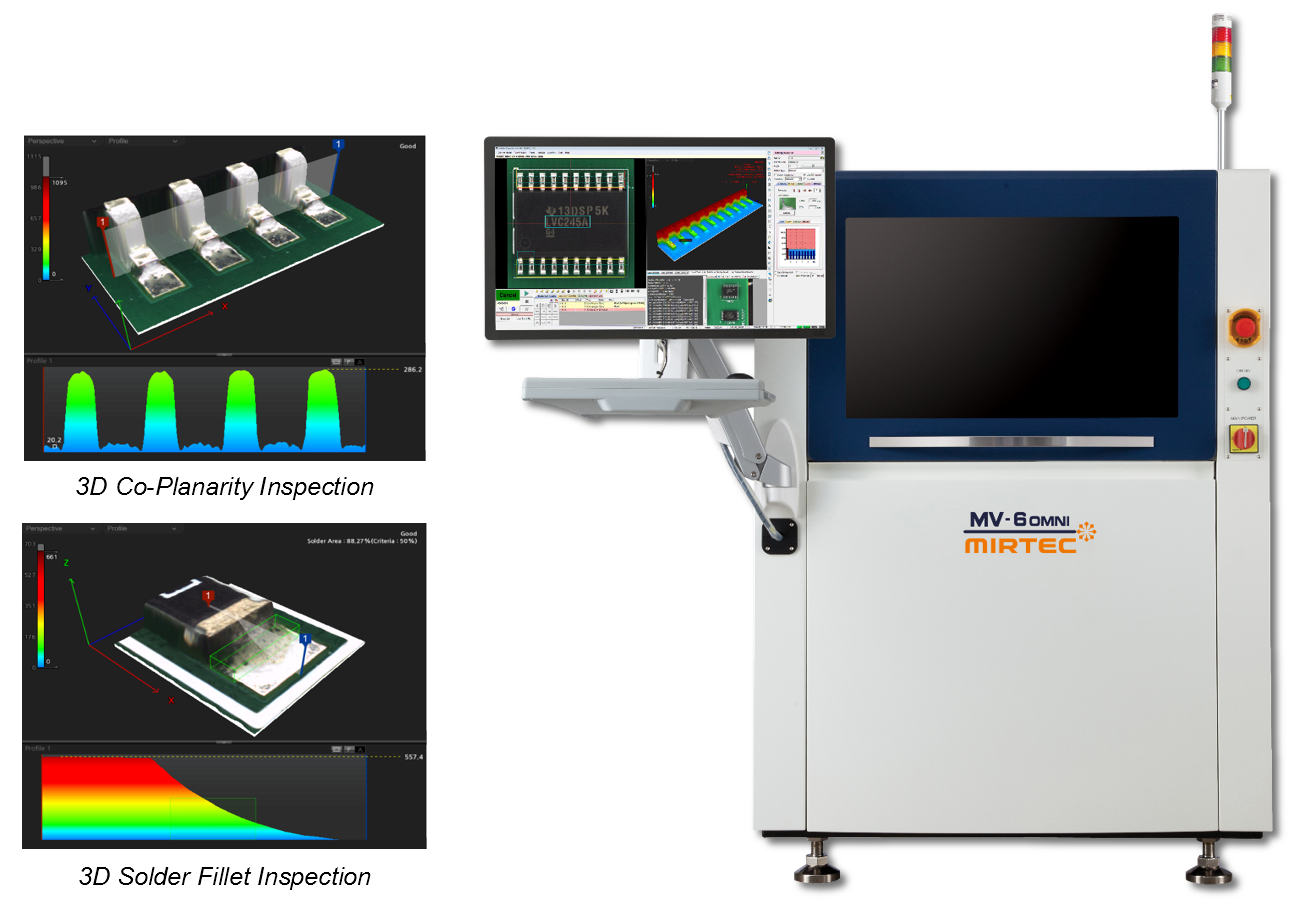

The industry acclaimed MV-6 OMNI 3D AOI Machine combines MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera Technology with their proprietary OMNI-VISION® 3D Digital Tri-Frequency Moiré Technology to provide precision inspection of SMT devices on finished PCB assemblies. MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera System is designed and manufactured by MIRTEC for use with its complete product range of inspection equipment. MIRTEC’s proprietary Digital Tri-Frequency Moiré Technology, provides superior 3D inspection of SMT and Thru-Hole devices up to 25mm tall.

The industry acclaimed MV-6 OMNI 3D AOI Machine combines MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera Technology with their proprietary OMNI-VISION® 3D Digital Tri-Frequency Moiré Technology to provide precision inspection of SMT devices on finished PCB assemblies. MIRTEC’s exclusive 15 Mega Pixel CoaXPress Camera System is designed and manufactured by MIRTEC for use with its complete product range of inspection equipment. MIRTEC’s proprietary Digital Tri-Frequency Moiré Technology, provides superior 3D inspection of SMT and Thru-Hole devices up to 25mm tall.

This award-winning technology yields precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.

This award-winning technology yields precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-6 OMNI machines feature four (4) 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.

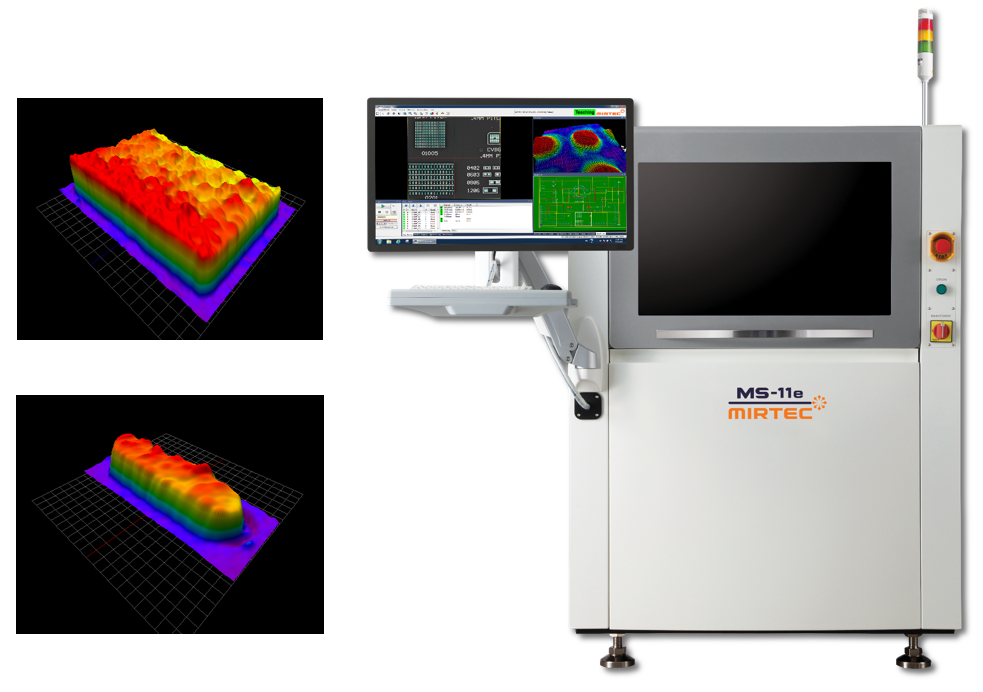

MIRTEC’s award-winning MS-11e 3D SPI Machine is configured with an exclusive 15 Mega Pixel CoaXPress Camera System, providing enhanced image quality, superior accuracy and incredibly fast inspection rates. The MS-11e uses Dual Projection Shadow Free Moiré Phase Shift Imaging Technology to inspect solder paste depositions on PCBs post screen print for insufficient solder, excessive solder, shape deformity, shift of deposition and bridging. The MS-11e uses the same robust platform as MIRTEC’s MV-6 OMNI Series.

“Electronic Manufacturers like Absolute EMS are becoming ever more selective in purchasing equipment that will add value to their business and provide them with a, much needed, edge in this highly competitive industry,” said Brian D’Amico, President of MIRTEC’s North American Sales and Service Division. “Our ultimate goal is to help our valued customers increase their profitability by improving production yields and reducing costly rework. We are extremely pleased to partner with Absolute EMS and are equally committed to their goal of continuous quality improvement. We look forward to a long and prosperous relationship between our two organizations.”