To keep pace with constantly advancing technological ecosystems, automation has become a focus area for innovation, efficiency and delivering quality results. One of the significant areas where automation is making impact is in embedded systems.

Embedded systems are characterized by their ability to operate with minimal human intervention, often in real-time, and are integral to the functionality of many devices we rely on daily. The integration of automation into these systems is changing the way they are designed, developed, and deployed, leading to enhanced performance, reliability, and scalability.

Current challenges of automation

A typical embedded system development platform includes multiple jumpers, switches, and buttons for enabling various hardware (HW) configurations like boot modes, programming mode or enabling different HW features. Due to this it becomes difficult to automate and truly validate embedded board and software for all HW configurations remotely or via automation.

While this can be solved using mechanical arms and similar concepts, it is very costly and not time efficient, hence making it not practically a feasible solution. Another alternate solution is using development boards, but it deviates from actual testing scenario.

Proposed Solution

We will explore the use of circuit isolation techniques and the adoption of the Jenkins ecosystem for continuous integration and continuous deployment (CI/CD). Circuit isolation ensures that test controller can configure the embedded systems under test safely and reliably by preventing electrical faults and interference from affecting the system’s performance while Jenkins provide a robust framework for automating the software development lifecycle of embedded systems. Jenkins, an open-source automation server, enables developers to build, test, and deploy code efficiently and consistently. By integrating Jenkins with embedded system development, teams can achieve faster iteration cycles, improved code quality, and seamless deployment processes.

The proposed solution shares a cost-effective solution with easy to implement method to overcome above mentioned limitations.

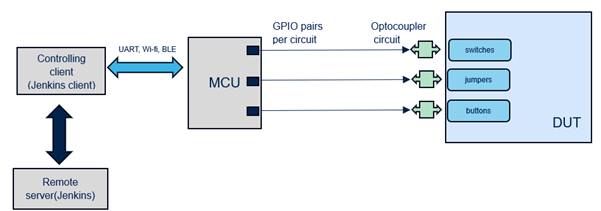

Figure 1 shows the block diagram of automation architecture where a small footprint microcontroller can be used to control an isolation circuit connected to the junctions of switch/jumper/buttons of embedded device under test (DUT). Isolation circuit (e.g., Optocoupler) ensures circuit safety. In the current demonstration NUCLEO-F401RE board (MCU) is used to control the optocoupler circuit connected to boot modes switches and reset button of STM32MP157F-DK2 board under test (DUT). Jenkins will issue remote commands to MCU.

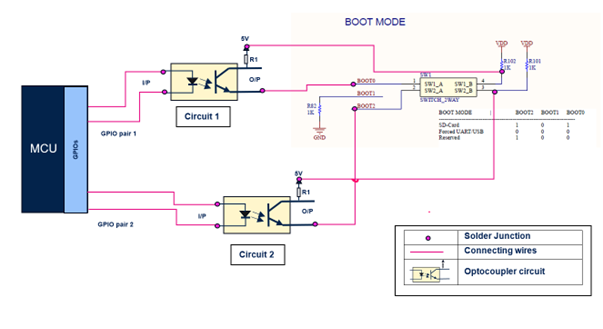

Figure 2 demonstrates the circuit diagram where MCU can control the state of two-way Switch SW1. VDD is connected to one end of output and R1 register is added to limit current. The value of R1 is based on the embedded device specification. In the default state, the physical switch is put in off state. Then depending on which boot combination we want, MCU will enable the output side of Optocoupler circuit.

For example, to put STM32MP157F-DK2 in SD card mode, GPIO pair 1 and GPIO pair 2 will be put in HIGH state. This will short output circuit and achieve 1,0,1 combination for SD card boot configuration. A similar circuit is present at the embedded device Reset button. After changing configuration, one can trigger reset to boot in desired hardware configuration.

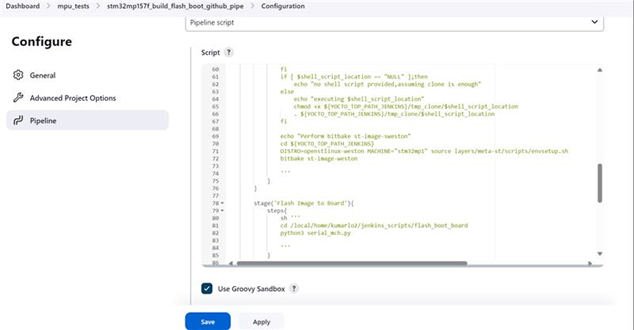

Jenkins is used to remotely send commands to NUCLEO-F401RE board through a computer containing automation scripts (python and shell scripts) which translates commands to configurations and sends it to MCU to change the device under test (DUT) state as explained above. Using this setup, one can manage all HW configurations remotely. The above arrangement successfully enables the developer to remotely perform board programming / flashing, toggling boot switches and configurations on STM32MP157F-DK2.

Python scripts are present on PC (Jenkins client) controlling MCU and Jenkins is used to invoke these scripts via Jenkins pipeline/scripts.

Scope and Advantages

The proposed solution can be extended to various embedded boards due to the small circuit size that can be easily connected to DUT. Also, a single MCU can control multiple circuits depending on the count of the GPIOs available on a given, multiple DUTs can be controlled. Another advantage being the low cost of circuits and MCU’s and solution is flexible due to multiple options being available to control it (UART, Bluetooth, I2C, SPI, Wi-Fi). Although the solution needs one controlling client which is used to control the Automation system remotely, one client can be used to control multiple Automation systems and thus making the solution scalable and reliable in every aspect as hardware configurations are also tested.

Future work

Embedded systems can include pin connections at desired switches and buttons, then the need for soldering is eliminated and one can simply connect MCU and isolation circuit to achieve complete and reliable automation.