ASMPT at Productronica India

From September 13 to 15, ASMPT will be present at the Productronica India trade fair being held at the Bangalore International Exhibition Centre. The main focus of the activities at Booth PC 01 in Hall 4 will be on the areas of production systems, software, and process optimization.

India’s electronic industry is one of the fastest growing in the world, with total sales for 2023 forecast to be US$12.59 billion, with an expected growth rate of 11.08 percent (CAGR 2023–2027). To achieve this, Industry 4.0 and process optimization will play a particularly important role. Especially in demand are flexible, modular and manufacturer-independent systems of the type presented by ASMPT, the industry’s technology leader as well as the world’s largest supplier of SMT equipment.

The ASMPT booth will feature a stencil printer from the flexible DEK TQ series in combination with the Process Lens HD optical solder paste inspection system, and a live demonstration will show the placement of 0201m components with the high-speed SIPLACE TX placement machine. In combination with this platform, ASMPT will also demonstrate on-board inspection, and stereo measurement technologies.

Other focus areas of ASMPT’s show presence will include intelligent software solutions and process automation, with presentations being divided into four thematic areas:

Programming

Using the latest SIPLACE Pro software and WORKS applications, ASMPT will demonstrate virtual product creation, recipe programming, offline setup and verification, and production planning.

Process optimization

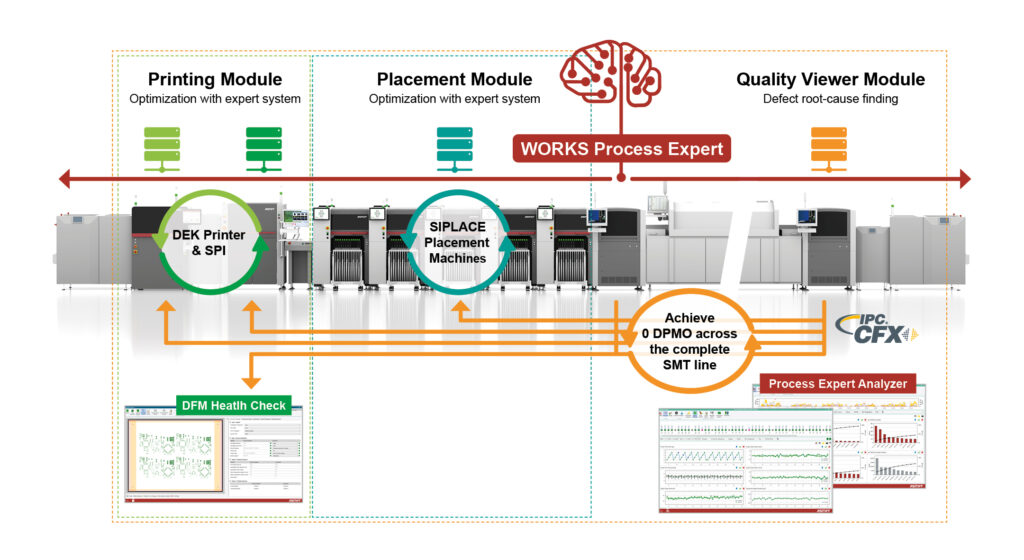

Here, everything will revolve around the combination of the Process Lens SPI system and the WORKS Process Expert software from ASMPT. The demonstration will show how manufacturers can achieve zero DPMO in solder paste printing with the help of proactive process optimization, intelligent error cause analysis, and user-friendly visualization.

Monitoring

With the help of illustrative use cases, ASMPT will present the WORKS Performance Monitor for the real-time display of the production status in the form of KPIs as well as the WORKS Command Center for efficient staff deployment across multiple lines. Another highlight will be the MES solution for electronics manufacturers from Critical Manufacturing, a member of the ASMPT Group.

Service 4.0

Here, visitors can get information about the state-of-the-art training programs offered by the ASMPT Academy, the new ASMPT Web Shop, and the AI- and NLP-based Virtual Assist application for technical and maintenance teams. Live demonstrations will present remote access to a machine GUI, the integration of third-party systems into Factory Equipment Center, the software for enterprise-wide asset and maintenance management, and many more applications that make maintenance and problem solving easier in electronics manufacturing.

“Especially in a market that is growing as rapidly as India’s, innovative solutions for improving productivity and monitoring in the SMT field are in great demand,” explains Mr Neeraj Bhardwaj, Head of Equipment Sales (South Asia) & Regional Management India (North) & Bangladesh at ASMPT. “Software is at least as important as our market-leading hardware.” Mr MN Prasad, Head of Equipment Service (South Asia) & Regional Management for India (South & West) & Sri Lanka at ASMPT, adds: “At ASMPT, we address almost the entire production chain and view electronics manufacturing as an intelligent and fully integrated system in which fast and precise machines interact seamlessly with software that is open and practice oriented. With standardized interfaces such as IPC CFX and our modular product portfolio, we allow the customer to decide at any time what he wants to automate and which systems he wants to use for this purpose.”

Image credit: ASMPT