The popularity of touch screen controls in research equipment, buttons, knobs, and serial connections are giving way to touchscreens, embedded systems, and even haptics. But does every instrument need a makeover?

Advanced equipments in the research industry need proper control, or monitoring for better practical applications. A chromatograph is of little use if no information about the health of the column is provided. A vacuum installation can be compromised if the readings from a leak tester cannot be trusted. Developers of scientific instrumentation are aware of this, and invest considerable time and money ensuring that users can properly achieve the results promised by the instrument’s design parameters.

However, developers must meet many goals—performance, reliability, throughput, and efficiency—and the final instrument design must balance cost with capability. In short, why install a fancy touchscreen control when a simple liquid-crystal display (LCD) will do? Why install a radio antenna when 95% of applications will necessitate a serial connection?

Increasingly, research professionals and original equipment manufacturers (OEMs) are looking to instrument control experts to help create a better, more functional experience for their customers. Developers recognize that users want more from their purchase than just a core capability. Better controls speak to the core engineering principles of the vendor, and when done correctly can help productivity and research results.

A new wave of controls for instrumentation

Initially, the invention of the transistor revolutionized conventional instrumentation control. Mechanical, vacuum, or even hydraulically actuated switches rapidly gave way to electronic knobs and switches. The transistor ushered in electronic control, and a new generation of instrumentation became available to OEMs.

Today, there are new technologies: large touchscreens; organic light-emitting diode displays; Bluetooth-enabled laboratory equipment; and compact, low-power radio transmitters. Driven by demand in the consumer electronics marketplace, these technologies are finding their way into laboratory equipment and examples abound.

One of the first research markets to experience a major transition in instrument control was test and measurement. High-accuracy electrical signal test equipment such as oscilloscopes, voltage testers, and data acquisition sets require a high degree of control of multiple parameters simultaneously. As instrument complexity and specification (such as the number of channels, or frequency range) has grown, developers looked for alternate ways to approach the user interface.

The capacitive touchscreen, much like the one in a smartphone or tablet computer, is smooth and protected by a single, solid piece of sealed glass. It eliminates many traditional buttons and knobs, and is well protected. Resistive screens consume less power and are tougher. Either type of screen is appropriate for research purposes if it is well protected.

Shimadzu Instruments North America, Columbia, Md., for example, offers a 10.4-inch touchscreen as a way to improve visibility and ease-of-use for its UH-X/FX Series of hydraulic testing machines. A machine that was once controlled with a series of buttons and knobs, and later by PC control, can now be adjusted using a touchscreen. Control parameters on the UH-X/FX, for example, are autotuned in real time, based on test force and strain values measured during testing. Bruker Optics’ (Billerica, Mass.) TANGO-T FT-NIR (Fourier transform near-infrared) spectrometer, released at Pittcon 2013, is controlled primarily by a touchscreen mounted to the top of the instrument housing, conserving bench space and eliminating clutter. Another example, JEOL USA’s, Peabody, Mass., In TouchScope (SEM), is controlled by a tablet-shaped touchscreen, where the company’s imaging software facilitates analysis and manipulation of output imaging. The advantage of using a touchscreen to control and monitor an imaging tool is even more significant, because users typically want to interact with the information, zooming, rotating, and adjusting quality to find areas of interest or answer research questions. There are some disadvantages, however.

This is true of much research equipment, which requires simultaneous fine-tuning of several pieces of equipment at once. Sometimes functions available in one section of an application on a touchscreen are difficult to access from another section. This could be one reason TI has not seen a widespread adoption of touchscreen technology in the scientific research space. Siegel speculates that the consumer market usually sets the trend, and popular capacitive touchscreens are general overkill for research instruments.

Another probable reason is the lack of standardization for these control products with respect to exacting laboratory standards. Researchers are accustomed to relying on NIST-traceable, ISO-standardized controller equipment that is capable of reliably conducting experiments. A researcher who needs this level of accountability and accuracy will turn instead to a company experienced in equipment control.

Control Company, Friendswood, Texas, for example, specializes in a wide variety of laboratory test, measurement, and control products, including data loggers and thermometers. They also offer controllers that do not feature any type of advanced wireless or touchscreen capacity. Their Walkaway Count-up Controller, for example, is simply designed to provide unattended, automatic operation of stirrers, heaters, or pumps at wattages up to 1,800. However, the instrument is fully NIST-traceable, with a certificate from an A2LA-accredited and ISO calibration laboratory. These types of instrument controllers do not need touchscreens, and probably never will.

Control resources for OEMs

Touchscreen technologies geared specifically for the research laboratory are available, however. Since 1985, Mosaic Industries Inc., Newark, Calif., has provided off-the shelf customized hardware solutions, from analysis to product design, for numerous embedded applications, including data acquisition and scientific instruments. Its expertise has grown to include touchscreens.

Mosaic’s human-machine interface solutions are geared toward a mix-and-match approach, in which off-the-shelf components are attached to an expandable I/O, allowing simple front-panel applications to complex networked SCADA systems.

By necessity, Mosaic must support complex industrial configurations that require graphical user interface (GUI) programming for hundreds of screens. Single-board computers are also supplied with real-time operating system software that interacts with the GUI software toolkit to allow the customer to design custom installations.

One example is the QScreen Controller, an LCD-based touchpanel display which incorporates all of these elements in a single embedded computer design that can be quickly attached to an OEM application that requires compact installation. Powered by a Freescale microcontroller, the QScreen is specifically designed for embedded systems, robotics control, scientific instrument control, and portable data acquisition.

The other factor that drives instrument designers to more traditional solutions is the need to protect their equipment from harsh environments. Companies like Mosaic provide specialized gaskets that keep out dust or liquids and resist outgassing and chemicals. Such conditions may adversely affect more advanced multitouch capacitive screens. They also use high-performance 3M adhesives and plastics to further protect screens from damage. Finally, electromagnetic interference can also cause problems in some research environments, which is why Mosaic specialized circuitry to form a barrier between the screen and the electronics.

Next-generation control

Not all laboratory tasks or fieldwork need such protective measures. In the field, researchers recognize that speed and convenience offer distinct advantages. Traditional wired controllers and heavy electronics are not always practical for people on the go. Handheld X-ray diffraction analyzers, for example, offer far less capability than their benchtop counterparts. But the ability to characterize mineral types simply by scanning the rock in a mine and comparing it to an onboard library attached to a simple touchscreen, offers a factor of speed and efficiency unmatched by traditional instrument controls. For some applications, particularly in test and measurement, new control technology is ideal.

Oscium Technologies, Oklahoma City, introduced an oscilloscope in 2012, which won a 2012 R&D 100 Award, that was entirely an application, or “app”, onboard an Apple iPad or iPhone. The iMSO-104 is the first mixed-signal oscilloscope packaged as a standalone software application.

It is limited in sample rate (12 MS/sec), frequency (5 MHz), and channel count (4 digital), but is proving useful to technicians who need a quick and dirty solution for on-the-go testing tasks. Other test and measurement companies have launched similarly inspired products. Electronic test equipment specialist B&K Precision, Yorba Linda, Calif., offers a full line of traditional laboratory power and test solutions, but early this year launched a new “pwrApp” software for use with Apple’s mobile computer products. pwrApp remotely operates the company’s XLN-GL power supplies It allows full monitoring and WLAN control of network-connected supplies through visual data graphing, alarms, and monitoring. In-app demos have the added bonus of teaching XLN novices, and offering an inexpensive glimpse at the technology for potential XLN buyers.

Even Austin, Texas-based National Instruments, one of the pre-eminent instrumentation control companies in the U.S., has developed an app for tablet-based touchscreen computers called Data Dashboard that lets users of its control programming software, LabView, create custom views and screens for mobile use of LabView applications.

Haptics on the horizon

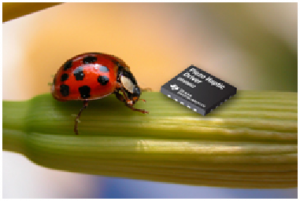

Although in existence for decades, the touch-based technology of haptics has started to become popular in handheld, portable, and touchscreen-enabled devices. Largely limited to the consumer market, haptics is now exercising an influence in the science and medical fields.

Haptics has been pursued by the automotive industry, which wants to improve driver safety with respect to the use of touchscreens. TI has also seen interest from a different type of research equipment customer.