Viscom AG will be presenting its latest inspection solutions at the world’s leading trade fair electronica in Munich, Germany, from November 15 to 18, 2022. At booth A3-642, the company’s experts will demonstrate how the highest quality requirements in today’s electronics production can be met with pinpoint accuracy – quickly, precisely and with all-round networking.

Smart condition monitoring, central and efficient IT management service, high-performance and scalable processing of large data volumes – Viscom will present these topics in the context of its new modular platform vConnect. The use of state-of-the-art methods enables complex manufacturing processes to be protected even better than before against unexpected disruptions and delays.

There will also be exciting reports on the practical application of artificial intelligence: Using the classification of inspection results as an example, possibilities will be shown for gradually establishing AI as a reliable co-decision criterion in quality control. Another AI focus will be the smart segmentation of voids detected by automatic X-ray inspection.

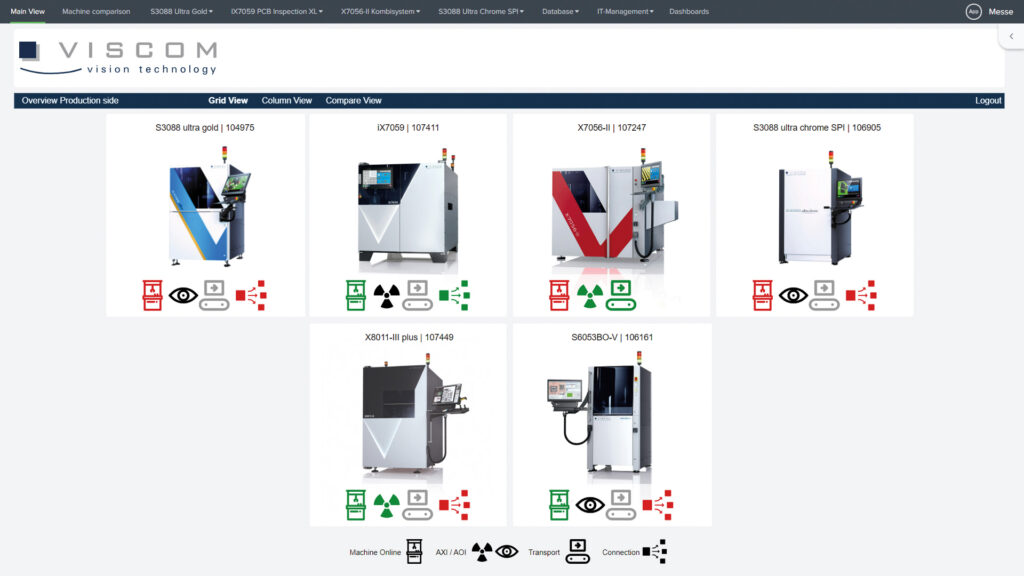

At electronica, visitors will gain an in-depth insight into Viscom’s wide-ranging system world. Among other things, the iX7059 PCB Inspection XL will be on display at the booth. The powerful 3D AXI system inspects PCBs up to 1600 mm in length for solder beads, damage, voids and many other potential defects. An innovative dynamic 3D image acquisition process, in combination with user-friendly software, generates complete volumes and individual CT slice images exceptionally quickly for accurate and repeatable measurements.

Potential applications of manual and semi-automatic X-ray can be demonstrated on the X8011-III 3D MXI system from Viscom. In daily practice, it supports process optimization and production start-ups, helps in processing complaints and is also ideally suited for quality inspections in high-mix low-volume production.

Viscom will present everything worth knowing about fast automatic optical inspection, including all-round smooth handling, on its S3088 ultra gold 3D AOI system – which is now used very successfully by customers worldwide. Special features of wire bond inspection will be explained on the S6053BO-V. With the aid of height information, for example, even precisely specified loop shapes can be reliably inspected with this equipment. With vConnect, users have a transparent view of the availability and performance of all inspection systems in use and the associated peripherals