The removal of fish scales — referred to as descaling — is an important early stage in a fish processing plant’s production line. Historically, descaling was a process carried out by hand, but although this practice is still very much the norm in less developed economies, the bulk of scale removal today is carried out by mechanized fish descalers.

The benefits of automation

Like other stages of fish processing, fast and efficient descaling is vital to ensure hygiene and freshness are maintained and to achieve the ever-larger yields demanded by retailers and end consumers.

PERUZA’s modern and efficient solution

Latvian food processing and automation specialists PERUZA have been designing custom and modular solutions for the fish processing industry for over 30 years. The company’s current catalog contains a vast selection of processing plant machinery that meets the complete end-to-end requirements of the fish processing industry, and among those solutions is a modern and efficient fish descaling machine.

The PERUZA fish descaling machine

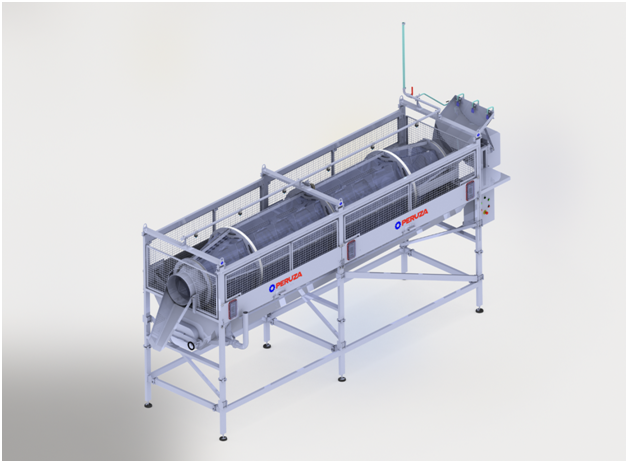

Peruza’s fish descaling machine is based around a stainless steel drum with a series of interchangeable blades. The apparatus is held inside a metal frame, and includes a shoot to receive payloads of fresh fish, and another to eject the descaled products from the drum.

The descaling machine in operation

The descaling machine works by receiving fresh fish into a tray and delivering them into the main drum. The rotating descaling drum’s blades scrape the scales from the infed fish, as a water shower sprays the drum to rinse away the removed scales into a collection bath with a drainage pipe at one end. Depending upon the type and quality of products added to the machine, the descaler for fish can be adjusted for both speed and drum angle.

The PERUZA fish descaler’s main benefits

Unlike outdated machinery or hand processing methods, PERUZA’s fish descaler enables very high production rates to be achieved by processing plants. The design of the descaler from easily washable and food contact compliant materials also enables greater production line efficiencies with minimal downtime, and is easily operated by a single technician.

PERUZA descaler overview:

- Types of fish processed: Sardines and other pelagic species

- Processing capacity: Up to 2,5 MT per hour

- Equipment dimensions: (LxWxH ) 3500mm x 1235mm x 2050mm

- Operators required: 1

- Key features: High capacity and continuous workflow

In conclusion

With ever greater demands being placed on fish processing plants around the world, labor-intensive and inefficient production methods are rapidly being phased out in favor of automated alternatives. The PERUZA fish descaler is an integral part of the Latvian automation specialist’s modular solutions, enabling processing facilities to achieve high yields over shorter periods of time.