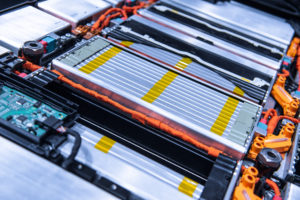

Electrolube, the global manufacturer of specialist electro-chemicals, has announced the success of its ER2221 resin for the protection of EV batteries in popular two wheeler vehicles in India. Electrolube’s customer, one of India’s leading two wheeler manufacturers, approached Electrolube, widely known as the solutions people, to help improve a thermal management issue in one of their key products. Initially, the ER2188 encapsulation resin was proposed as a viable solution. At first, ER2188 proved effective, however, when battery numbers increased, it became apparent that the ER2188 resin wasn’t flowing into narrower areas. In light of Electrolube’s global expertise, Electrolube India collaborated with their UK Technical counterparts to find a better solution for the customer. Electrolube’s UK headquarters sent a sample of ER2221 for Electrolube India to test with the customer. The resin proved to effectively create a protective shield around the battery and enabled excellent adhesion, low viscosity, UL94 V-0 Flame retardancy, high temperature resistance, thermal conductivity and retention of characteristics throughout the thermal cycling process.

Electrolube has a vast portfolio of encapsulation resin solutions but selected the ER2221 epoxy potting compound for this particular application because of its excellent high temperature resistance and high thermal conductivity. ER2221 is coloured black with an operating temperature of 150°C and an advanced thermal conductivity value, in comparison to other encapsulants, of 1.20W/m.K. The viscosity of the mixed system is also low in comparison to other resins with a similar filler loading. This allows the mixed resin to flow easily between components and devices with limited spacing. The fillers used in this resin are also non-abrasive meaning that there is less wear on dispensing machinery. The ER2221 displays excellent characteristics throughout thermal cycling and has proven to be an excellent choice for encapsulating electronic devices requiring high levels of thermal resistance and protection such as automotive, aerospace, industrial or other applications which are subject to harsh environments.

Electrolube India’s General Manager, Padmanabha Shaktivelu comments, “The ER2221 black epoxy resin has proven to be a very successful solution to fully optimise the performance of the EV battery in the two wheeler vehicles. We responded quickly to the customer and collaborated with our UK technical team to find the most effective solution, a resource that the company as a whole fully employs, when required, to source the most pertinent solutions for our global customers. We are fortunate to have strong R&D support and technical expertise across multiple continents that enables us to provide reliable solutions rapidly and efficiently to our customers.”

Electrolube India’s General Manager, Padmanabha Shaktivelu comments, “The ER2221 black epoxy resin has proven to be a very successful solution to fully optimise the performance of the EV battery in the two wheeler vehicles. We responded quickly to the customer and collaborated with our UK technical team to find the most effective solution, a resource that the company as a whole fully employs, when required, to source the most pertinent solutions for our global customers. We are fortunate to have strong R&D support and technical expertise across multiple continents that enables us to provide reliable solutions rapidly and efficiently to our customers.”

Ron Jakeman, Electrolube’s Managing Director, comments, “The ER2221 encapsulation resin is an excellent choice to protect the two wheeler electric vehicle batteries due to the high exposure to chemicals, moisture, mechanical shock and vibration resistance, which is critical in this location and application. For a dynamic and growing electronics industry that we now have in India, our collaborative capabilities and bespoke solutions are eagerly being sought after by local manufacturers, particularly as the industry seeks expert guidance to help improve processes, productivity and ultimately the quality and reliability of their end-products.”

Due to the growing need to reduce air pollution levels across India, the electric two wheeler market in India stood at around $27 million in 2017 and is forecast to reach $200 million by 2023. Other factors contributing to demand for electric two wheelers in India include their affordability by leading automobile manufacturers, Government incentive schemes and increasing distributor and dealership networks. The increasing demand is likely to result in a wide product portfolio for electric two wheelers, which will also increase India’s exports of 2 wheeler EVs and go some way to positively influence the country’s market during the forecast period.

As an EN9100 Quality Management System certified manufacturer of specialist chemical products supplying the world’s leading manufacturers of electronic, industrial and domestic devices, Electrolube is a trusted provider of high performance chemical solutions, formulated with the utmost responsibility to the environment and operator.

For further information about the ER2221 resin and further products from Electrolube’s key product groups, which include conformal coatings, thermal management solutions, contact lubricants, service and maintenance aids and cleaning solutions, please visit http://www.electrolube.com.