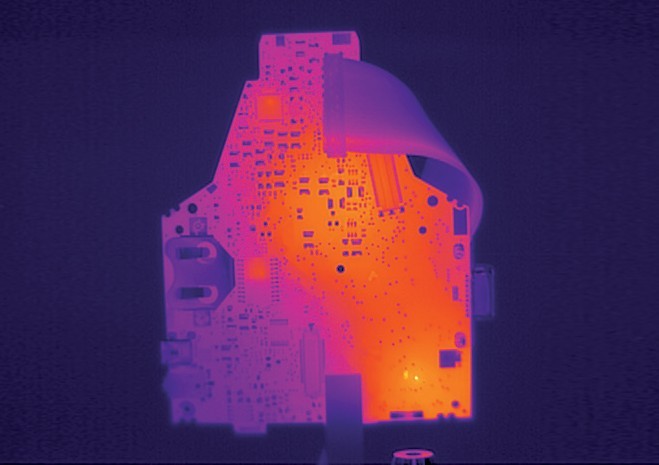

Precise visualization of critical temperatures. Electronic components are getting smaller and smaller. However, miniaturization means heat dissipation is also becoming more and more important. Modern microprocessors can give off more heat in relation to area than a hotplate and so present extensive challenges when it comes to designing circuits and dimensioning cooling.

Precise visualization of critical temperatures. Electronic components are getting smaller and smaller. However, miniaturization means heat dissipation is also becoming more and more important. Modern microprocessors can give off more heat in relation to area than a hotplate and so present extensive challenges when it comes to designing circuits and dimensioning cooling.

Thermographic analysis of heating and cooling properties is the resource of choice for checking and optimizing the thermal properties of electronic components and circuits. However, only high-quality thermal imagers can meet the challenges in electronics with optimum thermal sensitivity and the possibility of recording radiometric video sequences.

The challenge.

The challenge.

Even tiny components can generate a lot of heat on densely packed circuit boards in modern electronic equipment and thus impair the function of adjacent assemblies or even the whole circuit. In particular, continuous heat generation over a long period of time can have a negative effect on the functional capability and service life of a device. Quality assurance in electronics is therefore dependent on the design of the circuit board layout and the positioning of the components ensuring that the heat which arises can be dissipated effectively at all times.

The solution.

Thermography is an effective tool when it comes to understanding and optimizing the thermal behaviour of circuit boards and electronic components. The testo 890 thermal imager is the resource of choice for quality assurance here. The high-resolution infrared detector with 640 x 480 pixels and a focusing distance of less than 10 cm enable precise consideration of all components. The intelligent interplay of the system components enables even small components and fine structures to be monitored to a size of 113 μm mathematically – a precision which is currently unique on the market.

In addition to instantaneous heat distribution, heat generation can also be comprehensively checked and documented over a longer period of time thanks to radiometric video measurement and the possibility of recording thermal image sequences. The testo 890 thermal imager records the thermal processes for this and transmits the data directly to a PC. There, the recording can be stopped and analyzed at any point you wish. What makes it

special is: the corresponding temperature reading is available for every pixel on every individual image of the video. This means that thermal developments can be precisely analyzed and optimization measures undertaken if necessary.

special is: the corresponding temperature reading is available for every pixel on every individual image of the video. This means that thermal developments can be precisely analyzed and optimization measures undertaken if necessary.

The advantages.

Quality assurance does not just depend on meaningful thermal images and sequences, well thought-out analysis and processing of the measurement data also play a crucial role in terms of the documentation of the test processes.

The IRSoft analysis software developed by Testo analyzes thermal images, captures fully radiometric video sequences, displays the heating processes of defined measuring points as a temperature-time diagram and creates customizable reports.