Increase rigidity by 2.5 times and improve cooling efficiency by 30%

The company held the “Thermoelectric Semiconductor Tech-forum” on the 20th at LG Science Park in Seoul and introduced this thermoelectric semiconductor to the industry’s experts.

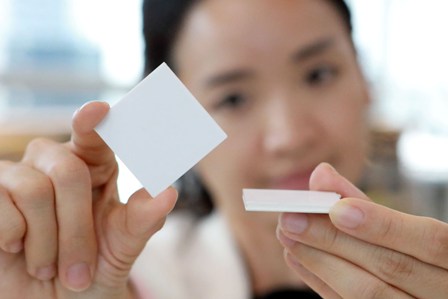

The thermoelectric semiconductor is a component can perform the cooling and heating functions by providing the component with electricity and can use temperature difference to produce electrical power.

It uses the “Peltier effect”, which generates heat on one side and cools on the other side when electricity runs through the semiconductor, as well as the “Seebeck effect”, which generates electric power when there is a temperature difference between both sides.

LG Innotek adopts the nano-polycrystalline material independently developed by the company. The nano-polycrystalline material was created by realizing an ultra-fine crystalline structure in the scale of nanometers, meaning one over a billion meters. The company could improve the rigidity and efficiency of the material compared to those of the previous single crystalline material and expands the application range to vehicles and ships.

The material has rigidity that is higher than that of the single crystalline one by more than 2.5 times, which is an advantage in that this new material can be used in vehicles and ships of which the materials can be easily broken by vibrations.

Also, the semiconductor employs an independent module structure with minimized heat resistance, which gives it cooling efficiency 30% higher than that of a single crystalline thermoelectric semiconductor module, lowering electric power consumption by as much as 30% during a cooling process at the same temperature.

Home appliances such as refrigerators and water purifiers can benefit from smaller sizes and lower noise levels when they are equipped with LG Innotek’s thermoelectric semiconductor. If the noise level of a small compressor-type refrigerator is 29dB, it can be brought down to as low as 19dB if the product uses the thermoelectric semiconductor. This value is even lower than the noise level in a broadcasting studio (20dB). Home appliances can also be made smaller and slimmer than the compressor-type products by up to 40%.

Its technology can be applied to the communication sector as well. If the product is applied to data transmission devices such as optical transceiver for communication, the temperature of optical communication components can be maintained at a constant level, which can minimize data loss. Optical communication components that fail to maintain a constant temperature level can have problems such as wavelength fluctuation and output decrease, which deteriorate data transmission efficiency and may affect communication performance.

Another advantage is that, when the semiconductor is applied to vehicles and ships, the waste heat generated from their operation can be converted into electricity, which can reduce both the amount of required fuel and the harmful gas emission. For a 1600cc diesel car as an example, if its fuel efficiency is 18km per liter, applying the thermoelectric semiconductor can improve the efficiency by 9~12% and up to 19.8km per liter. Applying the thermoelectric semiconductor to ships provides the benefit of lowered carbon dioxide emission, which can give the ship builders an edge in responding to the ‘Global Sulphur Cap 2020” set by the International Maritime Organization (IMO) and expected to undergo an update and become stricter in 2020.

According to TechNavio, a market research company, the size of the global thermoelectric semiconductor market is expected to grow from last year’s 471.55 million USD to 626.73 million USD in 2020.

The company official said, “LG Innotek is now capable of providing a total solution that encompasses R&D, production, and quality management of the thermoelectric semiconductor element modules.”