Mark Patrick, Mouser Electronics

It is no secret that globally we have to reduce greenhouse gas emissions. In support of this, the European Union is aiming that, by 2050, levels will have been cut by 80%. The automotive industry will need to make a significant contribution although, in the US, this has already started through the Corporate Average Fuel Economy (CAFE) standards, which have already made a significant impact. The CAFE standards may be reviewed by the Trump administration but, even as they stand, a 49 MPG average will need to be in place by 2022.

A key factor in whether these standards are met will be the rate at which electric vehicles (EVs) and hybrid-electric vehicles (HEVs) are accepted by the market. Bloomberg New Energy Finance is estimating that, by 2040, over one-third of vehicle shipments (41 million units) could be EVs. To achieve this will require a step-change in the purchasing patterns of major economies such as the US, China, UK, Japan, France and Germany as shipments of EVs there are below 1.5%. However, Norway is leading the way at over 20% and the Netherlands has significant sales at around 10% of the total.

One of the key hurdles to be overcome with consumers is that of ‘range anxiety’ – the concern that EVs (and HEVs to an extent) are not yet suitable for long journeys – or that recharging while ‘on the road’ will take too long. While the fundamental power technology is rapidly advancing, it is still in an early stage that not only means that it is not yet optimised, but also that it is relatively expensive – another hurdle to be overcome.

Clearly the power electronics have further to go, either more capacity in the same space, or delivering more range from the same energy levels. If the on-board inverters can be made more efficient then not only will less energy be wasted, but they will require less cooling and can be more dense. The efficiency will deliver more range for the same amount of charge and the smaller size will reduce weight, which will also have a positive impact on range.

Semiconductors are fundamental to any modern power system performance and with the emergence of wide bandgap technologies such as silicon-carbide (SiC) or gallium-nitride (GaN) significant progress is being made. In almost all areas (electron mobility, resistance (RDS[ON]), switching speeds, breakdown voltages and thermal conductivity, these new materials are superior to silicon (Si). As such, they can support significant improvements in efficiency and thermal performance in the inverter and other power circuitry. These inherently reliable technologies will deliver smaller and lower cost automotive power conversion, with increased range due to the higher efficiency.

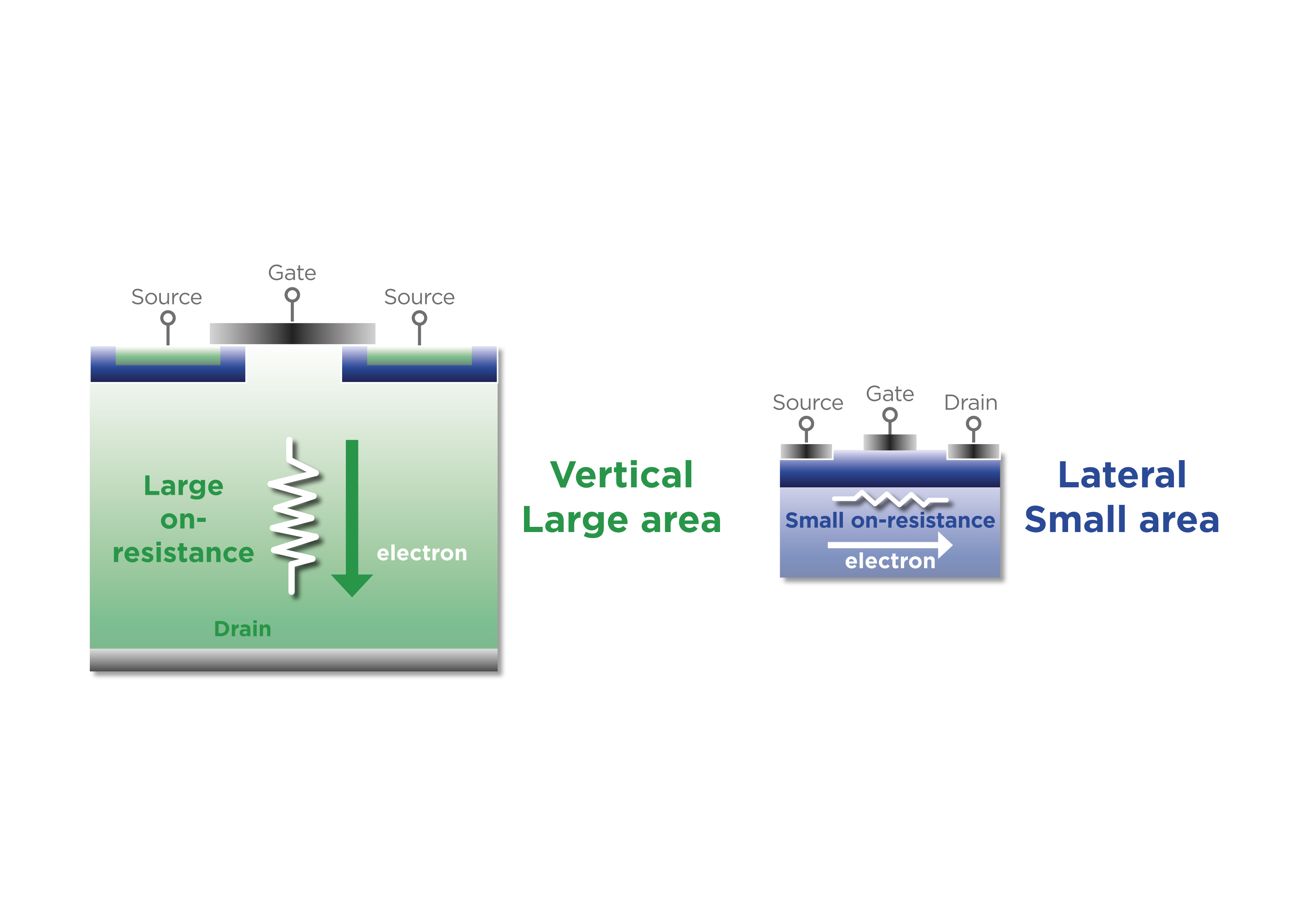

One leading example of wide bandgap devices is the GS6650x GaN-based devices from GaN Systems. These 650V devices incorporate proprietary Island Technology™ that saves space by dispensing with bus bars and allow current to be drawn vertically from the device, thereby reducing inductive losses. This also enables greater Figure of Merit (FoM) values that reduce the need for a trade-off between saturation voltage and switching losses. The GS6650x are packaged in a compact form factor using proprietary GANPX™ packaging that ensures excellent levels of thermal resistance and inductance.

Another example of this technology is Panasonic’s X-GaN™ enhancement-mode power transistors that are also based on wideband GaN technology. With increased breakdown voltages (> 600 V), these devices contribute to efficiency improvements and also save space due to their small size and low external component count.

Another method of improving losses is to combine advanced insulated gate bipolar transistors with SiC-based Schottky rectifiers. By replacing Si-based freewheeling diodes, the GA100SIC devices from GeneSiC substantially increase switching performance.

Any design engineers working on next-generation automotive power inverter technology would benefit from considering these advanced wide bandgap devices for their designs.

Although these new devices are not yet ‘mainstream’ their ability to deliver faster switching speeds and handle the high voltages associated with automotive batteries means that they will, almost certainly, form the foundation of future EV/HEV powertrains.