Thanks to optical attenuation and intelligent adapter construction

Individual components must become increasingly powerful due to the miniaturization of electronics. This also applies to LEDs. In the automotive sector for instance, these are already moving into power spectra far beyond 500 lm per individual LED. However, they are in part also being processed up to more than 1000 lm in modular design. This development also means a new challenge for measuring technology. That’s why Prüftechnik Schneider & Koch also offers the measurement of ultra-bright LEDs in the LaserVision-LED AOI and function test system.

“Different supply voltages for the circuit boards, the testing of so-called “long boards” as well as the testing of all LEDs obtainable on the market — including ultra-bright LEDs — are requirements that a universal test system has to cover these days,” explains Ronald Block, managing director of Schneider & Koch. The LaserVision LED test system was developed for exactly these tasks. Complete testing of the circuit board up to a length of 1500 mm is made possible in this connection. This encompasses AOI testing and function tests as well as testing of the LEDs with regard to light parameters. Thus 100% testing can be achieved in the in-line process.

“Different supply voltages for the circuit boards, the testing of so-called “long boards” as well as the testing of all LEDs obtainable on the market — including ultra-bright LEDs — are requirements that a universal test system has to cover these days,” explains Ronald Block, managing director of Schneider & Koch. The LaserVision LED test system was developed for exactly these tasks. Complete testing of the circuit board up to a length of 1500 mm is made possible in this connection. This encompasses AOI testing and function tests as well as testing of the LEDs with regard to light parameters. Thus 100% testing can be achieved in the in-line process.

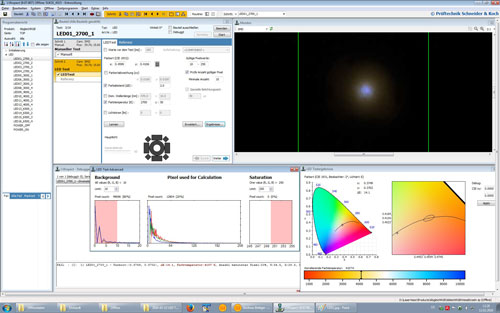

The testing of ultra-bright LEDs is challenging due to their brightness. Schneider & Koch has integrated optical attenuation and an additional camera to solve this problem. Since this doesn’t change the LEDs’ colour characteristics, the unit can be defined according to the maximum brightness of the LEDs to be tested. “The attenuator is designed so that future LED developments can also be tested with this option,” adds Block. The light filter, together with the illumination time, yields a very flexible system, which can be programmed for each LED. “Moreover, the customer can adjust the camera’s resolution as needed thereby optimizing the test speed”, Block continues.

Testing ultra-bright LEDs becomes a challenge particularly with assemblies in which the current can’t be influenced, because cameras can’t generally measure these LEDs without filters for brightness regulation. Power supplies built into the assembly in particular prevent the brightness from being set. In this case, testing has to be conducted with the Schneider & Koch method. “At the start of the project for this option, we set ourselves the challenge and developed a flexible system that enables especially manufacturing service providers to test normal to ultra-bright LEDs in serial production“, says Block describing the development philosophy at Schneider & Koch.

In order to guarantee the most stable values possible and a defined measurement time point, the possibility exists to supply the LEDs with current in advance. The so-called “pre-glow”, which leads to the LED’s maximum brightness, is engendered this way. This function is possible because the LaserVision LED is equipped with various sources, which can be flexibly interconnected via a matrix. Attention must also be paid to temperature management during the course of testing, particularly in LED assemblies with powerful LEDs. In these cases, heat dissipation can be implemented via the adapter. Electrical contacting can also be accomplished via the adapter. In in-line operation, this contacting is implemented via a contacting unit driven in parallel with servo-motors, which can be laidout both from below and from above. The special feature is extraction of the optically inspected areas. A hold-down mechanism was specially developed for this.

In the past, fibre-optic systems and sensor technology, integrated into the adapters as a supplement in electrical test methods such as ICT or function testing, were often used, but precisely these solutions were very expensive when a large number of LEDs had to be tested. So the cost of LED testing quickly reached a multiple of the actual adaptation costs. Since the measurement technology has to be arranged as close as possible to the LEDs to be tested and should ideally not be run over interfaces, these costs would therefore be incurred in each adapter used.

“The LED tester in fact also needs an adapter for electrical contacting during the in-line process, but the LED-measuring technology can be used universally over the entire extent of the assembly and is needed only once in the system. Therein lies the added value for the customer when using the LaserVision LED”, Block emphasizes. This can considerably reduce costs when testing several LEDs as well as when inspecting several applications.

Schneider & Koch will introduce the LaserVision LED’s functional principle at this productronica 2017 in Munich, Hall A1, booth 269.