Raghunandan N V, Technical Marketing Engineer, National Instruments spoke to EM about NI smarter test systems, new products and markets.

1) What are the design advantages of NI Modular instruments?

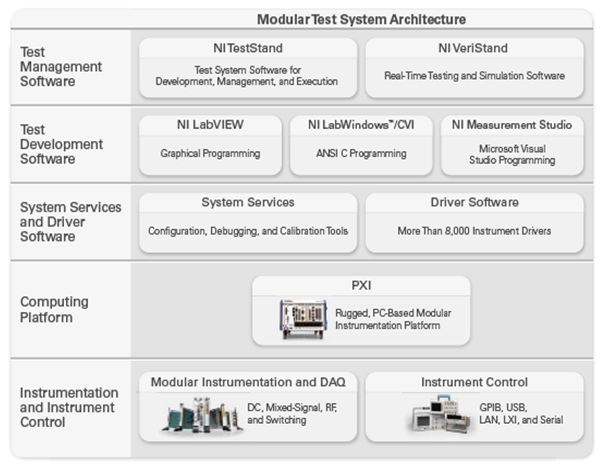

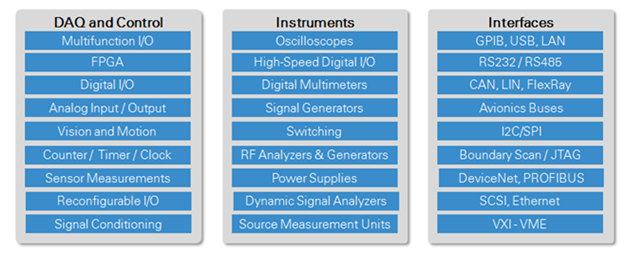

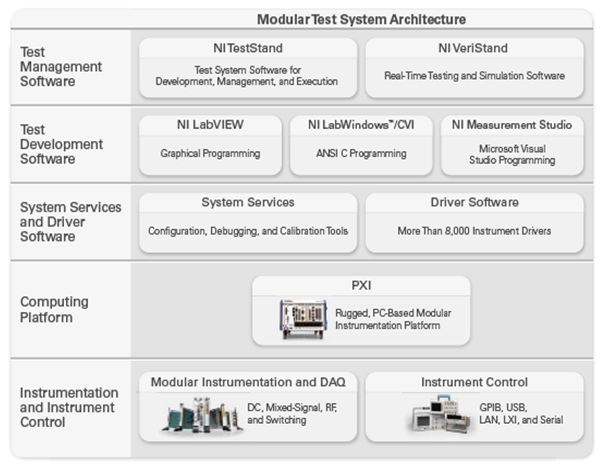

NI has designed & developed more 600 modules of the 1500 PXI products available in the market. These software-defined modular instruments allow the engineers to design and implement flexible test systems that can be repurposed quickly. PXI instruments provide a wide variety of I/O interfacing capabilities for ranging from DC to millimeter wave, including the industry’s highest resolution digitizer with 24 bits of resolution and the industry’s fastest, most accurate 7½-digit digital multimeter (DMM).

NI incorporates several proprietary and patented technologies in its modular instruments to ensure that they offer highest performance for timing, synchronization & calibration for data acquisition to ensure reliable measurements for today’s most demanding applications. PXI modular instruments from NI are compatible with both Windows Oss and real-time OSs for applications that require deterministic operation, and common Linux distributions. These modular instruments feature robust software interfaces which provide modular hardware interfaces for configuring and programming your tests. After an NI PXI modular instrument design has moved to full production, NI ensures each production unit is evaluated to meet its specification. Each modular instrument produced endures hours of rigorous testing to ensure that it reliably operates once deployed in its intended application.

NI incorporates several proprietary and patented technologies in its modular instruments to ensure that they offer highest performance for timing, synchronization & calibration for data acquisition to ensure reliable measurements for today’s most demanding applications. PXI modular instruments from NI are compatible with both Windows Oss and real-time OSs for applications that require deterministic operation, and common Linux distributions. These modular instruments feature robust software interfaces which provide modular hardware interfaces for configuring and programming your tests. After an NI PXI modular instrument design has moved to full production, NI ensures each production unit is evaluated to meet its specification. Each modular instrument produced endures hours of rigorous testing to ensure that it reliably operates once deployed in its intended application.

2) What are the new test approaches needed for smarter test system?

2) What are the new test approaches needed for smarter test system?

Smart devices are creating an inflection point in automated test for the test organizations. The test industry is turning to smarter test systems to help them with challenges of ensuring the quality of these smart devices at increasingly lower costs. To test their smart devices, organizations are transitioning from the status quo of rack-and-stack box instruments and closed-architecture automated test equipment to smarter test systems that deliver the ongoing connectivity and problem-solving capability to meet or exceed that of the device(s) under test.

The traditional and pervasive “vendor knows best” approach of closed, fixed-functionality instrumentation no longer scales technically or financially. The need to test infinite permutations of sensor, battery, computing and communications technology in devices both large and small against frequent software updates requires a smarter approach. Built on the “customer knows best” philosophy, today’s smarter test systems feature software and hardware tools inherently designed for customization. They offer an ecosystem of users and add-on IP that delivers more innovation than any individual vendor’s R&D team ever could.

3) How NI is addressing the demand for next generation device test?

NI has been at the forefront of revolution of ‘smarter’ test systems by offering modular hardware & software platforms that seamlessly integrate and provide the test engineers with the flexibility of software designed test instruments while leveraging the advances of Commercially-of-the-shelf (COTS) technologies. NI’s PXI portfolio includes IOs ranging from DC to millimeter wave; high-throughput data transfer bus based on Gen 3 PCI Express bus interfaces; sub nanosecond synchronization with integrated timing and triggering; the power and productivity of the LabVIEW and Test Stand software environments. Test Engineers looking to leverage the PXI platform, also have access to a vibrant ecosystem consisting of over 300,000 users, 10,000 instrument drivers and 1,000 partners. The vast library of third-party software available through the LabVIEW Tools Network and from other resources available within the ecosystem allows test organizations to build these next generation test systems faster.

In 2012, NI introduced a new instantiation of this “customer knows best” philosophy with the Vector Signal Transceiver (VST). Featuring a user-programmable FPGA and revolutionary RF measurement performance, the VST delivered unprecedented speed and insight in a single PXI device at an exceptional price. Not surprisingly, it rapidly became the best-selling PXI instrument ever while redefining RF instrumentation in the process. In the years since the VST introduction, NI has provided the power and flexibility of software-designed instrumentation to new instrument types and automated test applications. Meanwhile, Moore’s law and the big bang of smart devices proved that the software-designed instrument paradigm is the only paradigm that can sustain the pace of change because of its ability to evolve at the speed of software.

Take wireless for example. RF test instruments will require wider bandwidths to test future standards like 5G. Multiantenna & MIMO technologies require modular and flexible instrumentation that can scale from testing single-antenna devices to 8×8 MIMO devices and beyond. Finally, with wireless radios expected to cost a fifth of what they do today, future test equipment must be able to dramatically reduce the cost of test.

To exemplify ‘smarter’ and to provide unrivaled performance that meets both the current & scales for future requirements, NI launched the second-generation VST i.e. NI PXIe 5840. With 1 GHz of instantaneous bandwidth, it’s ideally suited for a wide range of applications including 802.11ac/ax device test, mobile/IoT device test, 5G communications design and test, RFIC test and radar prototyping. And though it features wider bandwidth, better measurement performance, extended frequency range, even more instrumentation capability and a larger FPGA for more advanced customization and signal processing, one thing hasn’t changed: engineers’ ability to make it whatever they need it to be.

4) What is NI’s approach towards 5G? And how does NI plan to support this new standard?

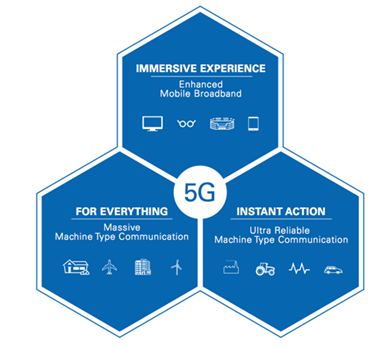

As the world’s researchers race to define 5G, it is becoming increasingly clear that just bettering the spectral efficiency of a 4G-based network is not enough to deliver the data rates, latency, and capacity necessary for the three high-level 5G use cases (Figure 1), defined by 3GPP to provide ubiquitous, instantaneous mobile broadband data.

As the world’s researchers race to define 5G, it is becoming increasingly clear that just bettering the spectral efficiency of a 4G-based network is not enough to deliver the data rates, latency, and capacity necessary for the three high-level 5G use cases (Figure 1), defined by 3GPP to provide ubiquitous, instantaneous mobile broadband data.

NI is collaborating with several top researchers focused on RF and wireless communications research—specifically fifth generation (5G) wireless communications through our integrated hardware and software approach and rapid prototyping offerings. This platform based approach helps engineers and researchers by accelerating their productivity. With our solutions, we make it possible to effectively and rapidly prototype wireless communication systems. As the technology evolves, so does our platform. Thus, allowing engineers innovate faster.

The unified design flow with LabVIEW and NI platform lets researchers develop new waveforms for 5G physical layer, build systems with massive channel counts (Massive MIMO/FD-MIMO), explore the high bandwidth and high throughput promise of mmWave bands for 5G and discover all the new higher layer design challenges associated with the future 5G system.

Conventional methods and disparate tools make prototyping expensive and can add years to development time as researchers struggle with long learning curves on tools, which detracts focus from the actual research. NI’s platform-based approach significantly reduces the time it takes to transition from theory to practical results in a real-world environment.

5) What are the key features of NI Wireless Test System?

NI Wireless Test System (WTS) is a multi-port, multi-DUT, multi-standard solution for accurate yet extremely fast production testing of wireless devices. This highly flexible solution is built on the NI PXI modular platform and is based on Vector Signal Transceiver technology. This system includes one or more RF vector signal analyzers and generators, and robust N-type DUT connectors to simplify connectivity for manufacturing test environments. It supports a variety of configurations including 2X2 MIMO and true parallel multi-DUT testing. NI WTS can be used in applications such as testing of WLAN access points, cellular handsets, infotainment systems, and other multi-standard devices that include cellular, connectivity, and navigation standards.

6) NI recently launched Industrial Internet of Things (IoT) Lab to Promote Innovation and Collaboration. What is the initiative behind it?

The NI Industrial IoT Lab focuses on intelligent systems that connect operational technology, information technology and the companies working on these systems. Designed with flexibility for the future, the lab’s operational focus includes areas such as microgrid control and communication, advanced control for manufacturing, and asset monitoring for heavy equipment.

Additionally, the NI Industrial IoT Lab fosters collaboration between different companies to improve interoperability. In this space, companies with expertise in communications protocols, controller hardware, I/O components, processing elements and software platforms come together to validate end-to-end solutions that can dramatically change the way businesses operate. Companies sponsoring the NI Industrial IoT Lab include: Analog Devices Inc, Avnu Alliance, Cisco Systems, Hewlett Packard Enterprise, Industrial Internet Consortium, Intel, Kalypso, OPC Foundation, OSIsoft, PTC, Real-Time Innovations, SparkCognition, Semikron, Viewpoint Systems and Xilinx.

7) Is National Instruments targeting specific technical institutes and universities for its products?

Since 1976, National Instruments has equipped engineers and scientists with tools that accelerate productivity, innovation, and discovery. This mission extends into education to provide educators, researchers and future scientists and engineers with affordable, relevant access to the same tools and technologies.

NI’s initial interactions with academia focused primarily on research. Over the years, we’ve expanded our focus to include education, offering teaching platforms for high schools, vocational schools, and universities. In addition to supporting researchers, we now provide academic institutions with comprehensive teaching solutions that deliver relevant, engaging, real-world learning experiences that equip students to “do engineering.”National Instruments has a presence in more than 7,000 universities worldwide.

8) Would National Instruments be looking forward to launch any product in the coming years for the Indian market specifically?

We announce all major product launches during NIWeek, our annual global conference for graphical system design. NIWeek is now well established and it has been running for over 20 years. The conference draws around 4000 attendees from around the globe and from many spheres of the electronics & control industries. Last year at NIWeek, with the Software Technology Preview, we provided a behind-the-scenes look at several of the innovations to be part and parcel of the future release. This year at NIWeek 2017, we will be showcasing the next generation of our software platform including LabVIEW. We also have a very exciting line up of other new product launches which will share the same keynote stage at NIWeek this year. Stay tuned and follow all news regarding our new launches here:

http://www.ni.com/newsroom/

9) Are you looking for any new markets or areas for your products? Why?

Technologies like autonomous vehicles and smart cities, V2X technology are revolutionizing the modern automotive industry. The wireless technology that enables this connectivity is constantly evolving – with new standards, new design challenges, and new test methodologies.

The demands of fully autonomous driving require that future vehicles use not just radar, but a sensor fusion technique that combines inputs from GNSS, radar, cameras and LiDAR. NI is looking to grow into this market by providing an Advanced Driver Assistance Systems (ADAS) test solution reconfigure typical test systems for module, ECU and vehicle testing. The ADAS Test Solution combines NI’s second-generation VST with banded, frequency-specific upconverters and downconverters designed to test the 76–81 GHz radar band with 1 GHz of real-time bandwidth. The system can function as an mmWave vector signal generator and vector signal analyzer because of this design. Engineers can program the VST’s FPGA with LabVIEW to use the ADAS Test Solution for radar target emulation, a technique in which test equipment emulates the radar cross section, range, radial velocity and angle of arrival of a particular object. This is essential for testing a radar system’s software and hardware.