TOKYO, JAPAN ― May 2015 ― Japan Unix, a solutions provider for manual and soldering automation, introduces laser shape rings. Choosing the best laser spot shape to fit components and land shapes can reduce circuit board problems.

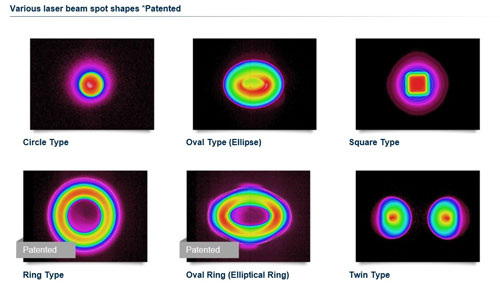

Laser shapes are available in more than just the well-known circle. It is important to choose the optimal shape to fit the components and shapes. Inadvertent burning of circuit boards or other troubles can be prevented by adjusting appropriate laser shapes such as an oval (ellipse) or a ring-shape. In addition, a beam-splitting technology provides “twin-spot laser,” which enables the simultaneous soldering of two joints. In addition to oval, ring and twin-spot, Japan Unix offers laser beam spot shapes of circle, square, ring and oval ring. (The ring and oval ring shapes are patented by Japan Unix.)

Laser shapes are available in more than just the well-known circle. It is important to choose the optimal shape to fit the components and shapes. Inadvertent burning of circuit boards or other troubles can be prevented by adjusting appropriate laser shapes such as an oval (ellipse) or a ring-shape. In addition, a beam-splitting technology provides “twin-spot laser,” which enables the simultaneous soldering of two joints. In addition to oval, ring and twin-spot, Japan Unix offers laser beam spot shapes of circle, square, ring and oval ring. (The ring and oval ring shapes are patented by Japan Unix.)

Japan Unix can help customers choose the laser type most suitable to their board patterns and components. For example, if the pad has an ellipse shape, customers should expose it with the oval type. Also, if the through-hole has black resin or other components on the back, Japan Unix suggests that customers use the ring type to prevent the laser burning it.

For more information about the importance of laser shape rings, watch the following videos:

• Verification video showing how incorrect laser shapes burn components: https://www.youtube.com/watch?v=iqjpVepqWbU

- Twin beams working two components simultaneously: https://www.youtube.com/watch?v=vRWr80bnCfg

Choosing correct laser beam shapes is as important as choosing soldering tip shapes for manual soldering. To find out more information about using optimal laser shapes, visit https://www.japanunix.com/en/products/laser/shapes.php.