As EDA tools gained commercial success in the late 1980’s, a need emerged for interoperability among the tools. There’s no doubt left in the minds of semiconductor device manufacturers that the processes required to build interposer-based and 3D IC devices are matured and ready for production. However, manufacturers are still out in the design community because designing 3D ICs still poses a challenge.

The possible reason is lack of knowledge & training. With any new technology paradigm shift, there needs to be an education to help design engineers find out how to get started. “Engineers are busy. Before they are willing to make a commitment – before a program manager is willing to take a leap of faith – he or she needs to be confident that all the pieces are there. To design in 3D, an efficient, streamlined 3D design flow is required. A suitable EDA, Electronic Design Automation Tool, could be a gateway to new era of IC designing. EM Media bought to you an in-depth analysis of role of EDA tools in 3D design & packaging.

The possible reason is lack of knowledge & training. With any new technology paradigm shift, there needs to be an education to help design engineers find out how to get started. “Engineers are busy. Before they are willing to make a commitment – before a program manager is willing to take a leap of faith – he or she needs to be confident that all the pieces are there. To design in 3D, an efficient, streamlined 3D design flow is required. A suitable EDA, Electronic Design Automation Tool, could be a gateway to new era of IC designing. EM Media bought to you an in-depth analysis of role of EDA tools in 3D design & packaging.

Currently available, Electronic Design Automation (EDA) tools exist to handle complex IC systems, and can therefore handle complex 3D designs as long as the software has the proper inputs from a foundry’s Process-Design Kit. EDA tools have evolved in complexity such that Design-For-Test (DFT) methodologies and technologies now exist to tackle 3D ICs. The IEEE 1838 working group on 3D interface standards is intended for heterogeneous integration, allowing for different IC process technologies, design set-ups, test, and design-for-test approaches. The standard defines test access features that enable the transportation of test stimuli and responses for both a target die and its inter-die connections. Die interfaces can be mis-aligned due to translation or rotation during assembly, and with die from different fabs at different geometries it can be non – trivial to ensure that the rights pins are connected. Using a precise EDA can helps us doing Die-stacking accurately. In short, “For successful adoption of 3D IC technology it is important, that EDA tools for IC designing and packaging has to keep pace with a fast-moving range of requirements being created by a dynamic and demanding industry.”

Before we move to our analysis on part of EDA tools in the technology of 3D ICs, we hereby introduce 3D ICs in brief.

3D IC Packaging refers to 3D integration schemes that rely on traditional methods of interconnect such as wire bonding and flip chip to achieve vertical stacks. 3D packaging can be disseminated further into 3D system in package (3D SiP) and 3D wafer level package (3D WLP). Stacked memory die interconnected with wire bonds, and package on package (PoP) configurations interconnected with either wire bonds, or flip chips are 3D SiPs that have been in mainstream manufacturing for some time and have a well established infrastructure. PoP is used for vertically integrating disparate technologies such as 3D WLP uses wafer level processes such as redistribution layers (RDL) and wafer bumping processes to form interconnects. 2.5D interposer is also a 3D WLP that interconnects die side-side on a silicon, glass or organic interposer using TSVs and RDL. In all types of 3D Packaging, chips in the package communicate using off-chip signaling, much as if they were mounted in separate packages on a normal circuit board. 3D ICs can be divided into 3D Stacked ICs (3D SIC), which refers to stacking IC chips using TSV interconnects, and monolithic 3D ICs, which use fab processes to realize 3D interconnects at the local levels of the on-chip wiring hierarchy as set forth by the ITRS, this results in direct vertical interconnects between device layers.

3D IC stacking or moving into the 3D by stacking multiple layers of IC will be the ultimate expression of CMOS technology. Whether stacking heterogeneous chips using through-silicon vias (TSV) or monolithic approaches to forming multiple active IC layers on a single silicon substrate, 3D ICs should be both smaller and faster compared to functionally equivalent 2D chips and packages. However, 3D ICs will likely always cost more than doing it in 2D, due to more steps being needed in manufacturing in terms of costing & expertise.

Significance of EDA Tools for 3D IC Design and Packaging

IC manufacturers understand that wasted design cycles are costly and as IC process sizes shrink, the complexity of the design grows. EDA tools are necessary to save time, reduce cost, and shorten design cycles, because they automate numerous tasks and provide feedback that enables designers to identify and correct design challenges before entering the costly prototype and manufacturing phase. Time-saving is also a critical factor, to be considered. With silicon manufacturers and device makers looking to pack an increasingly-powerful processing punch into ever-shrinking devices while simultaneously reducing their electricity consumption, building efficient power management into initial semiconductor design has become something of an obsession for the current generation of IC designers. Designing IC with such concerns for dedicated products need extremely accurate EDA tools that can work on critical parameters. Depending on the design, emulation can be a hundred times faster than using a software simulator to verify power intent and run a lot more tests and get better coverage for the device overall. The greater speed allows more scenarios to be explored and so identify power issues in the context of the full system early in the design process.

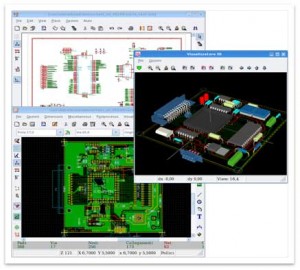

A user-friendly EDA tools help to increase the number of designers able to analyze and understand the architectural trade-off (performance, power, cost, etc.) of available alternatives and how they can impact the manufacturing process (throughput, yields, quality, and reliability), or will broaden market acceptance of 2.5/3D ICs, drive yield-learning and cost-reduction efforts. The use of path-finding or EDA tools will enable designers to make better choices when faced with a myriad of options including the use of true 3D ICs, 2.5D, or some other form of stacking using package-on-package with either a flip chip die on the bottom package, an embedded die in the bottom package substrate, or a fan-out wafer level package solution (FO-WLP). Support from the EDA tool community will be essential and allow for the designer to think in 3D. While significant progress has been made, there are clearly improvements that are required. The lack of optimal EDA tools has caused many of the large IDM/ODMs and major fabless IC vendors to exert significant internal effort to enable engineers to design interposer solutions. This includes scripting and modification of existing EDA tools to adapt them for path finding, floor-planning, and design and verification of interposers. Now a days, fabless companies has the financial resources to buy or fund an EDA company to enable them to do a 2.5D/3D IC design. In many ways, this is similar to the early challenges with ASIC design, when multiple IP blocks were combined with custom logic into one die. According to Cadence, 3D ICs do not need an entirely new design system, but do require new design capabilities in architectural analysis, floor-planning, place and route, thermal analysis, timing, signal integrity, IC and package co-design, especially regarding thermo-mechanical interactions, and test.

3D-IC design touches on so many areas of chip design that tool suites are going to have to be updated in areas including some of them mentioned ahead. In the application areas of EDA tools, what is likely to be much more challenging, though, is to upgrade existing tools and methodologies so that they can handle multiple process technologies. The die and the interposer are likely to be on different technologies and so you will need multi-technology-aware tools. For example, for extraction, we’ll have to extract each element separately and then concatenate them to create a single design file. The system needs to handle heterogenous process nodes, it needs to understand TSVs, have updated routing strategies and a database to handle heterogeneous processes. It sounds like an evolution but it actually takes a lot to do. Some of the key application areas are:

3D-IC design touches on so many areas of chip design that tool suites are going to have to be updated in areas including some of them mentioned ahead. In the application areas of EDA tools, what is likely to be much more challenging, though, is to upgrade existing tools and methodologies so that they can handle multiple process technologies. The die and the interposer are likely to be on different technologies and so you will need multi-technology-aware tools. For example, for extraction, we’ll have to extract each element separately and then concatenate them to create a single design file. The system needs to handle heterogenous process nodes, it needs to understand TSVs, have updated routing strategies and a database to handle heterogeneous processes. It sounds like an evolution but it actually takes a lot to do. Some of the key application areas are:

- Circuit design and schematic capture for redistribution layers, interposer signal routing, shielding and power

- Place-and-route support, including TSV, micro-bump, redistribution layer and signal routing, power mesh creation and interconnect checks

- Design-for-test for stacked die and TSV

- Integrated memory test, diagnostics and repair systems

- Parasitic extraction support for TSV, micro-bump, interposer RDL and signal routing metal

- Circuit simulation for multi-die interconnect analysis

- Thermo-mechanical stress analysis of TSVS and micro-bumps in multi-die stacks

- Physical verification

- Extended design rule checking

- Chip-level functional verification

- Static timing analysis

- IR/EM/SI and other electrical analysis

- Assembly and yield

Major Points to Be Considered While Designing an IC Package with EDA Tools

Even though 3D integrated circuits show great benefits, there are several challenges for the adoption of 3D technology for future architecture design: Thermal management – The move from 2D to 3D design could accentuate the thermal concerns due to the increased power density. To mitigate the thermal impact, thermal-aware design techniques must be adopted for 3D architecture design. Design Tools and methodologies – 3D integration technology will not be commercially viable without the support of EDA tools and methodologies that allow architects and circuit designers to develop new architectures or circuits using this technology. To efficiently exploit the benefits of 3D technologies, design tools and methodologies to support 3D designs are imperative. Testing – One of the barriers to 3D technology adoption is insufficient understanding of 3D testing issues and the lack of design-for-testability (DFT) techniques for 3D ICs, which have remained largely unexplored in the research community.

Cadence Design Systems (India) Pvt Ltd

Mr. V.C. Patil, AE Director

Mr. Patil, joined us on this technological story with his expert views. As per Mr. Patil, there is a disruptive change in consumers’ demands in electronics products. Consumers now want miniaturized products with lots of functionality in a single gadget.This change in consumer requirements has driven rapid evolution in technology capabilities and business necessities for system companies in the past decade. In turn, semiconductor and chip designers have had to innovate at a phenomenal pace to keep up. The relentless ask for electronic chips with increased performance and power targets, and the growing demands from the computing and mobile industries has resulted in the development of three-dimensional integrated circuit of 3D-IC, a design process integrating multiple dies in a single package. Another key development that has added to the exponential rise in complexity of chip design is the march towards advanced nodes. Today, designers are working with 14nm and 10nm nodes. 3D-ICs with TSVs bring enormous possibilities to how a system can be built:

- Heterogeneous integration

- Improved performance

- Reduced power consumption

- Maximum functionality in a smaller form factor(end product miniaturization) to support numerous applications in networking, graphics, mobile communications and networking.

The only way to meet technology requirements is through increased use of design automation, and being able to complete the design virtually. Hence,EDA tools have a significant role to play in 3D-IC design and packaging. Charting the design pathways; place and route; addressing stacking considerations; floorplanning; TSV and microbump planning;and performance validation for signal integrity, power, thermal, timing are some of the areas where EDA is critical. EDA tools are also needed for final signoff verification that will need to include thermal, mechanical and power considerations in addition to traditional design rule checking.

Talking about design considerations he said, though 3D-IC holds a lot of potential, it is still an evolving methodology and there are number of design and verification challenges which need to be addressed. Some of the challenges involved are as follows:

System-level exploration

Different D architectures need to be taken into consideration for evaluation at a very early stage to get benefits from 3D-IC TSVs and make this technology cost-effective. System-level exploration for 3D-IC TSV technology is a convergence of silicon and packaging with the design, making it possible to conceive and design new architectures. Existing system-level exploration tools can provide early power, area, and cost estimates, and they allow what-if explorations across architectures, silicon IP choices, and foundry processes. However, to provide some guidance on trade-offs that system houses would have to make between cost, power, and performance, these tools need to be extended to serve stacked die implementations, package, and manufacturing considerations.

3D floor-planning

A TSV-aware 3D floor-planner must allocate optimized TSV resources with respect to logic gates as TSVs can be very large compared to logic gates (they add more wire length and extra coupling, which is mitigated by keep-out zones that add area).

3D implementation

A number of new considerations come into play when it comes to synthesis, placement, and routing for 3D-ICs. For instance, there are new layout rules that may be driven by features on adjacent die. The back-side redistribution layer (RDL) is a new layout layer. And given their size, TSVs themselves are a significant new layout feature. An implementation system that supports 3D-ICs must be made “double-sided aware,” taking into account both the top and bottom of each die. This may call for a new modeling and database infrastructure, TSV-specific tools, and support for a variety of stacking styles.

3D extraction and analysis

Extraction and analysis is quite complicated with 3D-ICs. Timing, signal integrity, power, and thermal gradients must be analyzed across multiple die and take packaging into consideration. Existing extraction and analysis tools must consider RLC parasitic for TSVs, micro-bumps, and interposer routing and they must be made 3D-aware. When is the right time to sign off? What are the appropriate signoff points? Can design rule checking (DRC) and layout-versus-schematics (LVS) run on the entire stack? Should and can timing be verified for the entire stack? Is there any crosstalk between die? These are some of the questions one needs to consider. Finally, for 3D-IC, electromagnetic interference (EMI) is a potential concern and a consideration for analysis tools.

3D DFT

For 3D-ICs, one of the most critical factors is design for test (DFT). While wire-bonded systems-in-package (SiPs) may have a few hundred interconnects, 3D-ICs may have thousands if not tens of thousands of interconnects. Even a single defective TSV can render an entire stack unusable. If individual TSVs have 99.9% yield, at least one defective TSV can be expected in a stack of 1,000 TSVs. To provide test generation, the wrappers should support both the internal testing of each die as well as all the inter-die interconnects logic and TSVs. In addition to the traditional fault models used for digital testing (stuck-at, transition, stuck-open, bridge faults), 3D-ICs require specific interconnect fault models to test the TSVs and micro-bumps. The package tool plays extremely important role. It should enable 3D DRC, stacked die capability (such as multi-story building support), and, most importantly, should have manufacturing-aware design rules embedded. Very complex IC placement configurations, heat flow management considerations, and integrated electrical analysis are essential. For designers this means that in addition to expanding EDA tools to be 3D-aware, they also have to start thinking in 3D.

Further he flashed light of Cadence EDA Tools. He said, even though 3D-IC technology has had challenges such as lacking standards and supply chain, the good news is that 3D-IC enablement is evolving. Cadence has been working closely with customers and ecosystem partners for the last six years to develop a methodology for 3D-IC starting from planning to implementation, test, analysis, verification, and ultimately signoff. Our 3D solution is validated and tested on several customer designs, and includes:

- 3D implementation (placement, optimization, routing) for custom and digital

- 3D verification and analysis

- Design for test (DFT)

- IC/package co-design and system analysis

- System in Package (SiP) capability

- Required 3D-IC IP such as Wide I/O controller and PHY

- System-level exploration

3D ICs can bring in a lot of advantages, and can be used in a wide variety of applications.

- Lower costs are possible, because all functionality including analog and memory does not need to move to advanced process nodes.

- It is easier to meet high interconnect speeds and bandwidth requirements, which will reach 100 Gbits/second for advanced memory technologies.

- 3D ICs allow miniaturization, saving space on the board and in the end product. They’re ideal for extremely compact mobile devices.

- 3D ICs can reduce power because big drivers are no longer needed. A 3D stack can use small I/O drivers with lower power. Further, reduced resistance-inductance-capacitance (RLC) helps reduce power.

- Interconnect between packages is reduced, allowing for faster performance and a better power profile.

- Time to market can be faster, thanks to modularity, the potential for “die reuse,” and the ability to leave analog/RF at higher process nodes.

- Emerging technologies such as photonics or MEMS can potentially be integrated into 3D stacks.

Conclusion

3D ICs let design teams implement entire systems cost effectively in ONE package. For the most part, existing IC implementation and analysis tools can be extended to comprehend a third dimension, and allow 3D designers to rely on familiar and proven tools. Equally important is the availability of accurate and complete manufacturing data and material characteristics provided to system and chip designers by foundries, substrate, and packaging providers as well as OSATs. Ecosystem partners that work in relative isolation on 2D ICs today will need to communicate and cooperate much more closely to design and manufacture cost-effective 3D ICs. Exchange formats, interoperability standards, clarification of hand-off responsibilities, may prove useful and will allow industry to be fully benefitted.