The latest generation of LDOs allows reductions to be made to the current required without having to totally sacrifice dynamic performance. By utilizing advanced semiconductor technologies and sophisticated design techniques, there are now LDOs available for which these compromises are much less dramatic. Rohm Semiconductor offers a broad LDO lineup in various package types and output voltages and currents to suit a range of automotive applications.

The latest generation of LDOs allows reductions to be made to the current required without having to totally sacrifice dynamic performance. By utilizing advanced semiconductor technologies and sophisticated design techniques, there are now LDOs available for which these compromises are much less dramatic. Rohm Semiconductor offers a broad LDO lineup in various package types and output voltages and currents to suit a range of automotive applications.

The demand for low-voltage, low drop-out (LDO) regulators is increasing because of the growing demand for portable electronics, i.e., cellular phones, pagers, laptops, etc.

LDO’s are used coherently with dc-dc converters as well as standalone parts. In power supply systems, they are typically cascaded onto switching regulators to suppress noise and provide a low noise output. The need for low voltage is innate to portable low power devices and corroborated by lower breakdown voltages resulting from reductions in feature size.

LDO’s are used coherently with dc-dc converters as well as standalone parts. In power supply systems, they are typically cascaded onto switching regulators to suppress noise and provide a low noise output. The need for low voltage is innate to portable low power devices and corroborated by lower breakdown voltages resulting from reductions in feature size.

Low drop out (LDO) regulator is a DC linear voltage regulator which can operate with a very small input output differential voltage. The demand for the low voltage, low drop out (LDO) regulators is increasing because of the growing demand of portable electronics.

LDO regulators are used to derive lower output voltages from a main supply or battery. The output voltage is ideally stable with line and load variations, immune to changes in ambient temperature, and stable over time. LDOs should have as low a difference between the input and output voltage as possible, called the dropout voltage. For example, in a battery-powered design using a lithium-ion cell connected to a 2.8 V LDO, the battery voltage can drop from 4.2 V (fully charged) to 3.0 V (battery empty) and provide a constant 2.8 V output provided the LDO’s dropout voltage is below 200 mV. In some systems LDOs are used for post regulation. The LDO connects to the output of a high-efficiency switching regulator and provides noise filtering, as well as a constant and stable output voltage.

One of the key challenges that design engineers currently face is minimizing the power consumed by the system they are designing. Employment of various low power modes can help to reduce consumption levels. The choice of low drop-out (LDO) linear voltage regulators used in a system design can impact greatly on the overall power consumption.

LDOs in Automotive Applications

Today’s autos often incorporate dozens of low-dropout (LDO) linear voltage regulators, for applications ranging from instrument clusters to body controllers to engine management systems. In virtually all cases, LDOs serve a critical function, providing a low-cost voltage output to devices that require fixed voltage.

The biggest market for LDOs is in automotive body controllers, for such applications as brake lamps, head lamps, turn signals and interior lights. They’re also being applied increasingly to gages on instrument clusters, as well as on most car audio systems.

Rohm Introduces New LDO Lineup for Automotive Applications

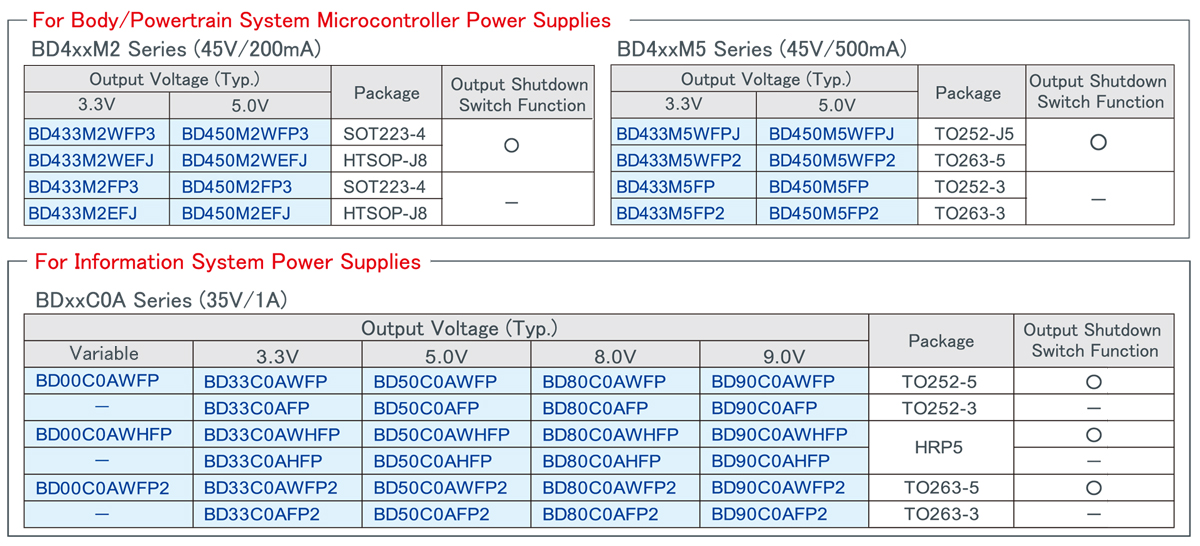

ROHM has recently announced the development of a new 16-model lineup of LDOs optimized for MCU power supplies in automotive body and powertrain systems. The new BD4xxMx series, together with the BDxxC0A series designed for power supplies in information systems such as car infotainment, bring the total number of automotive-grade LDOs to 43.

ROHM has recently announced the development of a new 16-model lineup of LDOs optimized for MCU power supplies in automotive body and powertrain systems. The new BD4xxMx series, together with the BDxxC0A series designed for power supplies in information systems such as car infotainment, bring the total number of automotive-grade LDOs to 43.

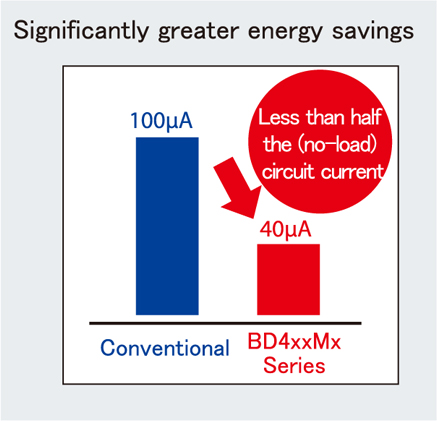

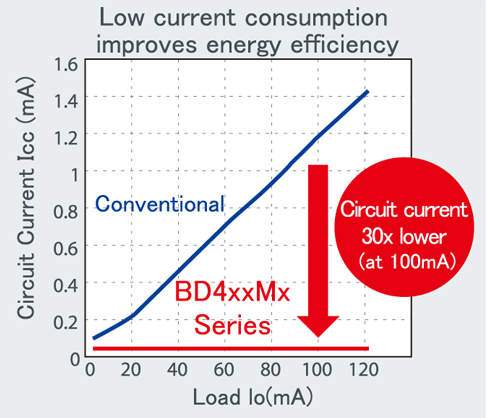

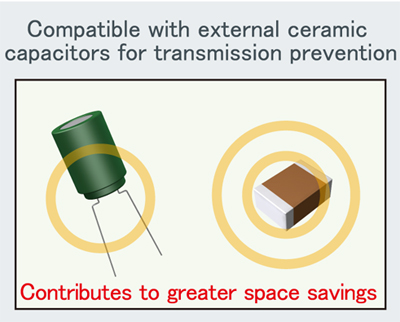

The BD4xxMx series utilizes state-of-the-art power system 0.35µm BiC-DMOS processes and takes advantage of ROHM’s renowned analog design technology to achieve less than half the no-load current consumption of standard products, contributing to significant energy savings. In addition, novel circuit design enables support for ceramic capacitors, eliminating the need for electrolytic capacitors for oscillation prevention, reducing both mounting area and costs.

In recent years as power supply ICs for automotive applications continue to increase in sophistication and functionality, there comes a greater need for an expanded lineup to cover a wide range of characteristics and application requirements – such as package type and output current – instead of simply focusing on developing an all-in-one solution.

In the automotive sector we are also beginning to see a shift towards parallel purchasing by companies to hedge against risks from natural disasters such as the Great East Japan Earthquake or the flooding in Thailand, as well as increased (global) standardization of commonly used products, which is only expected to accelerate in the future.

In the automotive sector we are also beginning to see a shift towards parallel purchasing by companies to hedge against risks from natural disasters such as the Great East Japan Earthquake or the flooding in Thailand, as well as increased (global) standardization of commonly used products, which is only expected to accelerate in the future.

In order to quickly respond to these solutions, ROHM offers a broad LDO lineup in various package types and output voltages and currents to suit a range of automotive applications. The BD4xxMx series is available in a range of form factors, from power packages that support harsh environments to ultra-compact, space-saving types, and in different output currents and voltages. ROHM utilized 0.35µm BiC-DMOS processes and takes advantage of proprietary analog design technology cultivated over many years to achieve an input tolerance of 45V along with high reliability to ensure compatibility with automotive applications. Additional features include a no-load current less than half that of conventional products as well as stable low current operation with load, contributing to lower set power consumption.

In addition, unlike conventional products, stable voltage output with no output fluctuations or oscillation is possible using just a small (1-10uF) external capacitance. This allows compact ceramic capacitors to be used, contributing to increase space savings.

Key Features

1.Less than half the current consumption of conventional products

The shift towards greater computerization in vehicles has led to an increase in the number of MCUs required, making it important to minimize power consumption for each power supply IC to improve system energy savings. The BD4xxMx series leverages ROHM’s market-tested analog design technology to reduce no-load current consumption by more than half while also providing stable low-current operation during loads (along with the BDxxC0A series).

The shift towards greater computerization in vehicles has led to an increase in the number of MCUs required, making it important to minimize power consumption for each power supply IC to improve system energy savings. The BD4xxMx series leverages ROHM’s market-tested analog design technology to reduce no-load current consumption by more than half while also providing stable low-current operation during loads (along with the BDxxC0A series).

2.Ceramic capacitor compatibility reduces mounting area and costs

Optimized design ensures stable voltage output with no output voltage fluctuations or oscillations with an external capacitance of only 1-10uF. This eliminates the need for larger external electrolytic capacitors, and allows smaller ceramic capacitors to be used, minimizing both mounting area and costs.

Optimized design ensures stable voltage output with no output voltage fluctuations or oscillations with an external capacitance of only 1-10uF. This eliminates the need for larger external electrolytic capacitors, and allows smaller ceramic capacitors to be used, minimizing both mounting area and costs.

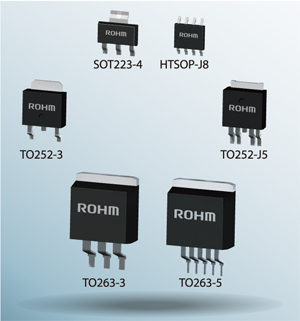

3.Multiple package types offered for broad compatibility

Redesigned circuitry that reduces the number of blocks, along with a reconfigured chip layout, make it possible to offer 6 different package types, from robust power packages that can withstand harsh environments to compact models suitable for high-density applications.

Applications

◇ Fuel Injection (FI)

◇ Tire Pressure Monitoring Systems (TPMS)

◇ Smart key

◇ LCD monitors

◇ HEV / EV inverters

◇ Body Control Modules (BCM)

◇ Heads Up Displays (HUD)

◇ Cluster systems

Automotive-Grade Lineup

Additional Information

Pricing: 100yen (per sample)

Availability: Now