By Mohit Sharma, Manager-Digital Transformation Services, Sasken Technologies Limited

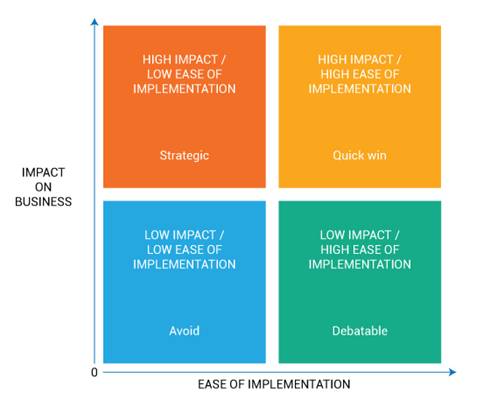

Across industries, pilots on blockchain network are taking place which demonstrates the value of blockchain and its acceptance in the ecosystem. This paper attempts to evaluate business use cases of blockchain in the Industrial domain and explains the 2X2 framework – Ease of Implementation and Business Impact.

Keywords—Blockchain, Manufacturing, IoT, Peer to Peer, distributed ledger, Industrial, Industry 4.0., Smart factory, IoT, Regulations & compliance, 2*2 Framework – Ease of Implementation and Business Impact, Decision matrix, IIoT

Introduction

In this paper, the term Industrials is used to refer to smart factories guided by the principles of Industry 4.0 which are the ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of Things (IoT) or the Internet of People (IoP). Increasing adoption of IoT in the industrial set up (IIoT) presents manufacturers with tremendous business opportunities but also puts them under the threat of hackers.

Gartner expects the ‘business value-add’ of blockchain will grow to slightly more than USD 176 billion by 2025 and it will exceed USD 3.1 trillion by 2030.

Blockchain technology can compliment IoT data to be securely transferred among related parties. Apart from securely transferring the data, there are many use cases of blockchain in the Industrial domain while meeting GS1 Standards.

Industrial Blockchain – Industry 4.0, IoT and GS1 Standards

Industrial 4.0., IoT and GS1 Standards for trace product across the full supply chain require:

- Distributed shared ledger that is tamper proof which means that once recorded, transactions cannot be altered

- The secured consensus from all network members and all validated transactions are permanently recorded which means that even a system administrator, cannot delete the information.

- Permission so that each member of the network has access rights for confidential information to be shared on a need-to-know basis

- Elimination or reduction of processes, speeding up transaction time and increasing efficiencies

Blockchain technology ensures that the ‘smart factory’ follows four guiding principles of Industry 4.0. – interoperability, information transparency, technical assistance, and decentralized decisions.

IIoT’s revolutionary solution of Predictive Maintenance is always under threat by hackers but blockchain technology can ensure secure data sharing with real users only without IoT Gateway.

GS1 standards for product traceability was debatable as no immutable shared ledger technology was available before the introduction of the blockchain.

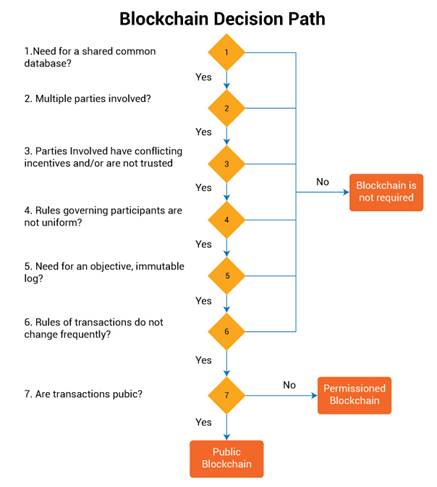

Blockchain Decision Path

Blockchain decision path is a simple method to check whether blockchain (private or public) is required or not.

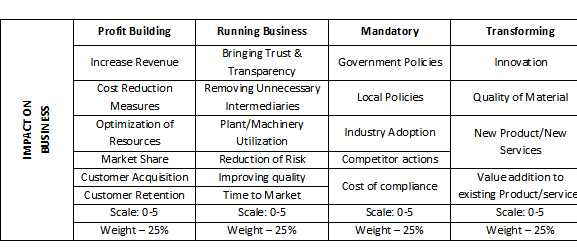

Impact on Business vs Ease of Implementation

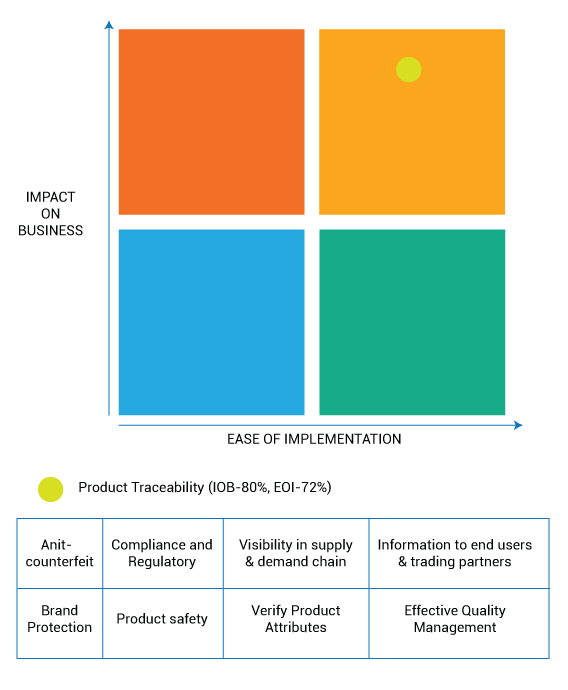

Weighted score based on different variables for both the axis i.e. ease of implementation and business impact framework is very useful and powerful while taking any decisions. In this paper, this framework is used to assess whether blockchain makes sense from a business perspective and to prioritize use cases subsequently.

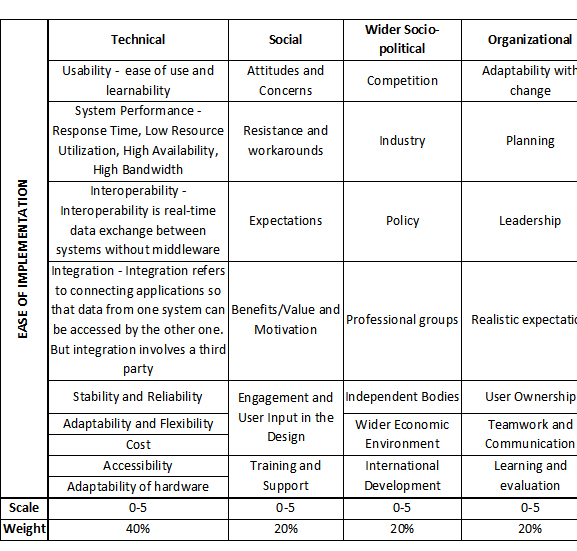

Ease of Implementation:

Factors deciding Ease of Implementation vary based on use case and stakeholders. There may be few factors of your choice not reflecting in the table below or your business may not consider few or any of these factors under Ease of Implementing. The weights to each factor and scale vary for each user.

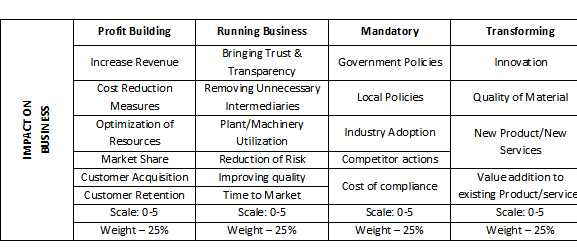

Impact on Business:

Stakeholders, especially investors, are more interested in knowing the Impact on Business. Calculating the Impact on Business is an even more difficult task compared to Ease of Implementation calculation.

Blockchain and Industrial Use case – Product Traceability Solution on Matrix

Blockchain and Industrial Use case – Product Traceability Solution on Matrix

There are a variety of supply chain solutions and technologies available today. The capability for ensuring traceability is commonly focused upon, to a varying degree, on specific links in the chain rather than across the complete end-to-end supply chain.

During an MIT Center for Transportation and Logistics roundtable, a shipper noted, “… there are many fragmented players, different technologies, lots of choices, and no single standard.”

This situation is further exasperated by the inability to communicate product lifecycle traceability across the partner trading networks. The complexity found across the partner network, in the context of traceability, is extended in part through the varying needs of each participant in the network. The depth and proper definitions of governance is a major component required for a comprehensive functioning network. The technology interoperability and integration needs of each partner required to support individual traceability requirements lead to a variety of information silos unable to support the broader ecosystem.

Blockchain Product Traceability Solution

For purposes of this specific use case, traceability will incorporate three dimensions:

- End-to-end traceability: Capturing all details from a raw material required to develop the product, final delivery, return and after-sale services

- Product characteristics: How the product is defined by the industry, organizations, consumers, etc.

- Regulatory concerns: Ensuring the traceable item meets compliance requirements.

Blockchain Product Traceability – Ease of Implementation

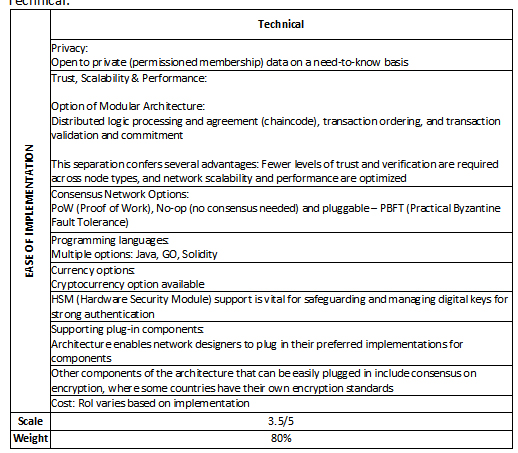

For Industrial implementation, a lot of frameworks and options are available right from Ethereum to Hyperledger. Yet, ease of blockchain implementation is a business challenge rather than a test of technology implementation as it involves connecting multiple parties across multiple processes.

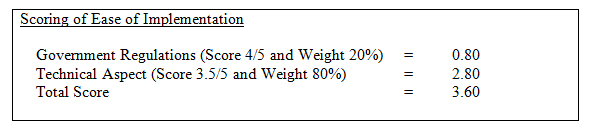

Stakeholders use their own derived framework to evaluate the investment but the above-designed framework is generic and can be applied to any business.This is flexible enough to include or exclude any factors and their weight based on user aspirations. In this estimation, only two aspects are considered – Government Regulation (20% weight) and Technical Feasibility (80%- weight) to calculate the Ease of Implementation.

- Government Regulations:

Majority of the countries including USA, Japan, China, South Korea and others have accepted blockchain technology as it brings about trust and transparency. Blockchain helps manufacturers in meeting the GS1 (Global Traceability) Standard and to comply with regulatory requirements and guidance on recalls. (Scale 4/5, Weight 20%)

- Technical

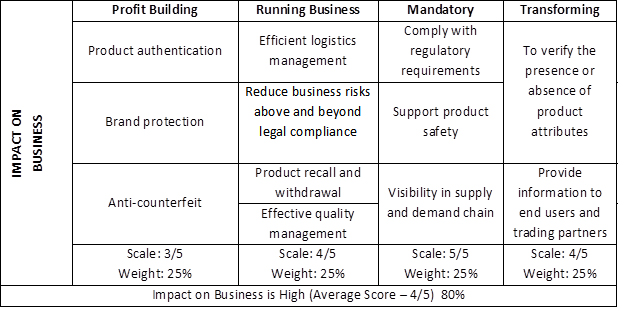

Blockchain Product Traceability – Business Impact

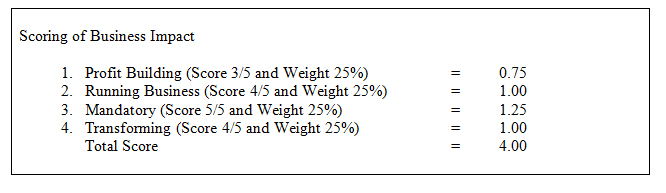

Expectation and judging criteria of each stakeholder differ but the basic questions remain the same – What is the profit? How does it help me in running the business smoothly? Is it mandatory to implement? Can it help in transforming the business?

Factors, scale, and weights can differ depend based on choice of stakeholders

Business Impact is 80 % (4/5) in this use case.

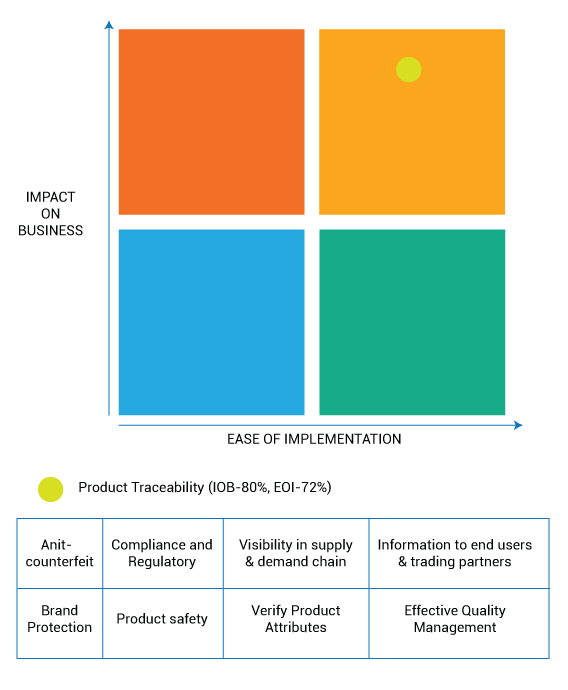

Conclusion

Blockchain Product Traceability Solution in the Framework – Ease of Implementation and Business Impact

Blockchain Product Traceability Solution in the Framework – Ease of Implementation and Business Impact

High Business Impact and High Ease of Implementation put the solution in the quick win quadrant as it provides solutions for eight business challenges. Blockchain technology has the potential to redefine enterprises, ecosystems, and economies. High Business Impact and Ease of Implementation make blockchain a quick win technology.

About Mohit Sharma

Mohit Sharma has rich experience in Business Analysis, Business Intelligence, Data Science, Machine Learning, Advance analytics, Digital Consulting and Social Media Strategy. He has immense exposure and delivered solutions in various industries such as Automotive, Banking, Health, Insurance, Manufacturing, and Retail. At Sasken, he is responsible for delivering business solutions to existing clients and new customers.