Power-management functions must be complex enough to handle the increasing number of peripherals and processor cores populating today’s mobile platforms. Power management must also deal with more complex charging scenarios, as today’s users are as apt to charge their devices from sources like a PC USB port or car charger as a conventional mains-powered charger.

Power-management functions must be complex enough to handle the increasing number of peripherals and processor cores populating today’s mobile platforms. Power management must also deal with more complex charging scenarios, as today’s users are as apt to charge their devices from sources like a PC USB port or car charger as a conventional mains-powered charger.

Power Management is one of the big concerns in IC design industry today. Power management chips are the key components in any device with a power supply, battery or power cord, which exist primarily to optimize power usage. In short, they serve as a bridge for electricity to flow through a system or device.

In particular, power management integrated circuits refer to circuits that range from applications such as managing the power used within a larger electronic system such as a cell phone, TV or computer to applications enabling new power saving technologies including smart meters and grids or more efficient lighting solutions.

Owing to increased consumption of electricity, more and more concerns arise regarding the efficient usage of energy such as in data centers, power strips and appliances like air conditioning etc.

These energy efficiency concerns are being solved by the power management chips by vast means. For e.g., power management chips facilitates efficient multiple charging sources, multiple supply voltages within a product.

PMICs have applications in the communication, IT, industrial, automotive, medical, defence and electronics sectors. A factor encouraging growth is the interest in energy-efficient technologies, in order to combat rising energy prices and consumer adoption of portable electronic devices. Alternative energy technologies used to harness solar and wind power are driving demand, as power semiconductors use power management integrated circuits to minimize energy wastage and ensure efficient power distribution.

Power management ICs are used to manage the accurate power flow in portable and handheld devices, such as cell phone power amplifiers and LED display, CPU, DRAM, Graphics, High Speed I/O and USB. In addition, under-voltage or other fault conditions are monitored to prevent damage to the system. The soft-start feature reduces stress on power supply components and increase product reliability. Implementation is typically done using analog integrated circuits but there is a strong trend to move towards digital or mixed signal implementation.

How far is the industry from commercialization?

The PMIC report indicates that energy-efficient technologies could reduce global electricity usage by up to 30% by 2025. Several types of power management IC include voltage regulators, motor control IC, Integrated ASSP Power Management ICs and battery management IC among others. Depending on the need and application the ICs are included in various devices and used accordingly. Among the various types of power management IC, Integrated ASSP Power Management ICs has the largest market as it is used in specific applications.

Manufacture of isolated AC/DC and DC/DC power supply controllers, and non-isolated voltage regulators, such as switching DC/DC converters and linear regulators, to PMIC and LED drivers for plug-in power modules, digital power, battery management and high-performance MOSFETs etc., can be done.

To capitalize on market opportunities in the new growth cycle, chipmakers need to make fundamental, structural improvements by means of improving research and development, innovative supply chains, transformation of sales force etc., This tends to attract more investments and revenues in the sector.

There are three key challenges to the designers of power management IC units. One is by adding additional functions to a device that will allow the user to operate several different applications at one time. Secondly size reduction of the IC so that is ideal for portable applications. Finally, the longer operating times for single or multi cell batteries.

Mr. Bhaskar Dhandapani, Country Sales Manager, Freescale Semiconductor Pvt. Ltd. points out key trends driving PMICs growth and important markets in this space.

Power management ICs have certainly become very important for the semiconductor industry and the electronics industry at large. Few key trends in this space are:

- One is for lower cost, simple PMICs, many of which are being integrated into their host IC’s package, thus becoming a system-on- chip (SoC) (e.g., entry-level, single-chip cellphone ICs with an integrated PMIC). These devices supply very basic features (many of the phones are voice only) to emerging cellphone markets.

- The other trend is to have more complex PMICs (for higher end stand-alone applications) become part of the chipset of the application. Examples of this are feature-rich cellphones or mobile computing devices.

Applications and Demands @ “Power management ICs are used in various applications in the telecom, aviation, automotive and industrial market. The usage of power management ICs have overtly increased in these industries specifically. Freescale’s Power Management Integrated Circuits (PMICs) provide highly integrated, high-performance power management solutions for a wide range of applications in the Automotive, Consumer and Industrial markets.

The key drivers have certainly been the influx of smartphones, tablets and laptops and consumer products largely. Growing demand of battery operated devices in automobiles, consumer electronics, industrial and military among others has led to the increase in demand of power management IC.

Opportunities for this market is huge. With the growing demand of smartphones, tablets, laptops and other consumer products, the power management ICs have become pivotal in the ecosystem. The ICs provide the management of voltage and current.”

Market Outlook @ “Semiconductor as an industry is growing manifolds. There have lately been several announcements to pace up the growth and the industry has also seen a greater acceptance across Asia-pacific. The power management ICs have played a very important role in the overall semiconductor market especially providing the back-end support in the high demand consumer durables. According to a new market report published by Transparency Market “Power Management IC Market” – the global Power Management IC market is expected to reach a value of USD 46 billion by 2019, growing at a CAGR of 6.1% from 2013 to 2019.”

Freescale Power Management Potfolio

PMIC based products have a lot of advantages like better battery life, longer life cycle and is more competitively priced. Freescale’s portfolio of Power Management products offer designers highly integrated solutions for power control. Our products enable longer battery life, smaller form factor, component count reduction, ease of design, lower system cost and improved performance. We have products for power management, highly integrated I/O, analog interfacing, backlighting, computing, networking, wireless, motor control and distributed control for a wide variety of today’s consumer, industrial and automotive products

Freescale’s i.MX Power Management Integrated Circuits (PMIC’s) are specifically designed for use with our line-up of i.MX multimedia processors. With integration levels targeted at specific applications within the consumer, industrial and auto-infotainment markets, Freescale’s PMIC’s are supported as part of our complete reference design platforms that include hardware and software solutions to enable fast time to market, with minimal effort for our customers, all back up with superior applications support from a single supplier. These PMIC’s integrate the full system power management functions, as well as battery management, backlight, interface and audio functions

Rohm New LDO Target Automotive PMICs

Automotive systems design is increasingly challenged for several reasons including the wide operating temperature range, strict EMC controls and transient requirements, constrained space, and the high-delivered quality levels expected by the car manufacturers (OEMs). Coupled with the increasing complexity of embedded processors and their support components (e.g. DDR memory), there are growing demands on power rails, making power supply design an even bigger headache.

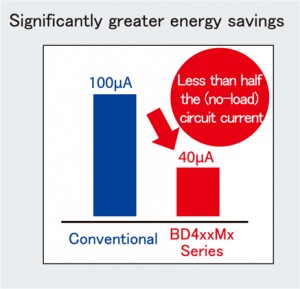

ROHM has recently announced the development of a new 16-model lineup of LDOs optimized for MCU power supplies in automotive body and powertrain systems. The new BD4xxMx series, together with the BDxxC0A series designed for power supplies in information systems such as car infotainment, bring the total number of automotive-grade LDOs to 43.

The BD4xxMx series utilizes state-of-the-art power system 0.35µm BiC-DMOS processes and takes advantage of ROHM’s renowned analog design technology to achieve less than half the no-load current consumption of standard products, contributing to significant energy savings. In addition, novel circuit design enables support for ceramic capacitors, eliminating the need for electrolytic capacitors for oscillation prevention, reducing both mounting area and costs.

In recent years as power supply ICs for automotive applications continue to increase in sophistication and functionality, there comes a greater need for an expanded lineup to cover a wide range of characteristics and application requirements – such as package type and output current – instead of simply focusing on developing an all-in-one solution.

In the automotive sector we are also beginning to see a shift towards parallel purchasing by companies to hedge against risks from natural disasters such as the Great East Japan Earthquake or the flooding in Thailand, as well as increased (global) standardization of commonly used products, which is only expected to accelerate in the future.

In the automotive sector we are also beginning to see a shift towards parallel purchasing by companies to hedge against risks from natural disasters such as the Great East Japan Earthquake or the flooding in Thailand, as well as increased (global) standardization of commonly used products, which is only expected to accelerate in the future.

In order to quickly respond to these solutions, ROHM offers a broad LDO lineup in various package types and output voltages and currents to suit a range of automotive applications. The BD4xxMx series is available in a range of form factors, from power packages that support harsh environments to ultra-compact, space-saving types, and in different output currents and voltages. ROHM utilized 0.35µm BiC-DMOS processes and takes advantage of proprietary analog design technology cultivated over many years to achieve an input tolerance of 45V along with high reliability to ensure compatibility with automotive applications. Additional features include a no-load current less than half that of conventional products as well as stable low current operation with load, contributing to lower set power consumption.

In addition, unlike conventional products, stable voltage output with no output fluctuations or oscillation is possible using just a small (1-10uF) external capacitance. This allows compact ceramic capacitors to be used, contributing to increase space savings.

Testing PMICs and Challenges

Latest Smartphone and tablets continue to advance at a rapid pace. On the component side alone, the latest mobile devices are moving towards 64-bit application processors, multi-mode RF front-ends, higher-end cameras and flashy LCD screens. Some systems even boast fingerprint scanners and heart rate sensors.

But an obvious part of the system continues to lag behind the curve—battery life. In response, Apple, Samsung and others have recently rolled out mobile devices that boast new and improved battery life. Still, the insatiable appetite for power-hungry software applications and wireless data is expected to keep battery life a pressing issue for some time.

One way to mitigate the problem is to channel the power more efficiently. To achieve that goal, OEMs are incorporating a new class of power management integrated circuits, or PMICs, into the system. Generally, PMICs are analog/mixed-signal devices, which are designed to regulate and control the power in a system.

In many respects, the power management IC is becoming just as critical, and possibly as complex, as their digital counterparts like the application processor and baseband. And as smartphone and tablets get more complex, OEMs are adding more power management chips in the same device. The shift toward more complex power management ICs for mobile applications presents some new and major ATE challenges. Like most suppliers of mobile chips, PMIC vendors are under pressure to drive down the cost and hit the market window. This, in turn, requires ATE with more channels, higher levels of parallelism and other features.

Going forward, the PMICs themselves likely will see an increase in digital complexity. For example, the fuel gage and the charger control IC, which have been separate chips, may get integrated into the PMIC. Wireless charging is another possible candidate for integration.