“LabVIEW has been an integral development tool for the pre-cooler testing and will be used for further development test systems.”

– Michael Hood, Reaction Engines Ltd

The Challenge:

To design and build a test system to validate the enabling technology for the world’s most powerful and advanced plane engine.

The Solution:

Using LabVIEW and NI CompactDAQ to create a test-bed that is both scalable and flexible in its implementation and allows for all of all the test data to be viewed simultaneously and logged at high speed for further analysis.

Read the Full Case Study

Author(s):

Michael Hood – Reaction Engines Ltd

Introduction

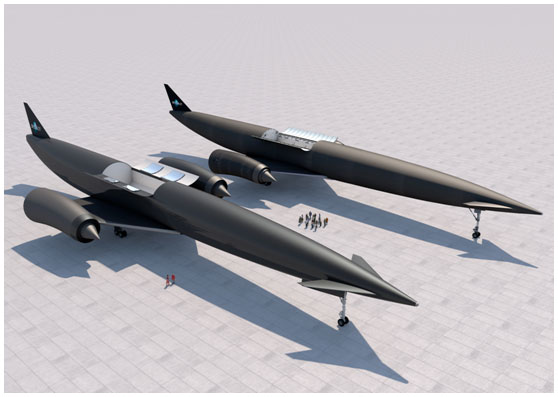

An aircraft that takes off from a runway, travels to the very edge of Earth’s atmosphere, delivers its payload or even travels into space, then heads back to earth and lands on the same runway it took off from. It sounds like science fiction, but Reaction Engines Limited (REL) has laid a solid foundation to make this a reality in the not-too-distant future.

Current space propulsion systems based on rocket technology alone place limits on the performance of launch vehicles, which leads to multistage vehicle configurations that are either expendable or only partly reusable. This results in complex launch systems that are both high maintenance and expensive to operate. REL’s Skylon space plane, a fully reusable single-stage launch vehicle, addresses these drawbacks and could revolutionize future access to space by providing more efficient and reliable launch operations.

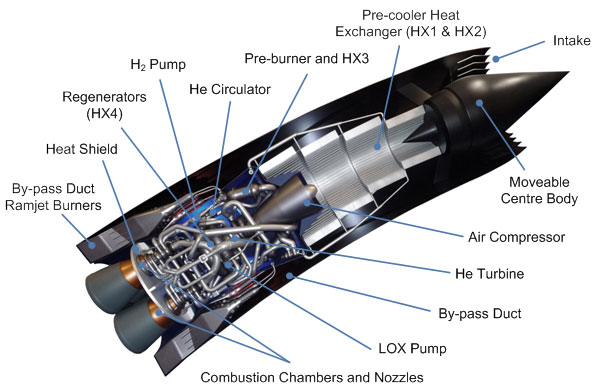

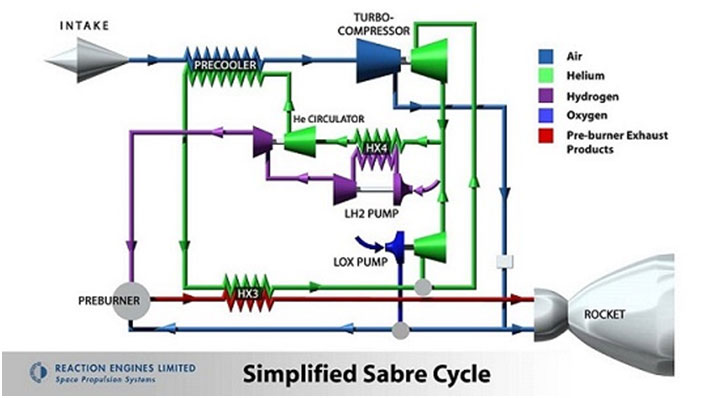

Fundamental to its design is the propulsion system that powers it from a horizontal runway launch right through to Earth orbit (up to 600 km). The Synergetic Air-Breathing Rocket Engine (SABRE) is a new type of rocket engine that incorporates elements of a jet engine into its design. The SABRE, and in particular its advanced heat-exchanger technology, provides a breakthrough in propulsion like that of the invention of the jet engine, which makes multistage launch vehicles a legacy technology. REL’s pioneering engine technology offers greatly improved reliability, a tenfold reduction in cost, and responsive access to space. No longer will space missions take months or even years to plan. REL’s Skylon space plane can take off and land from a runway, which means that a space mission can be conducted as easily as a commercial flight.

Plans for the Skylon plane are still in their infancy but the technology that provides the incredible thrust to weight ratio required to accelerate the plane to Mach 5.5 inside the atmosphere (over five times the speed of sound and over twice the speed of the world’s fastest air breathing plane, the Blackbird) and on to Mach 25 to break out of the atmosphere is already mature. Whilst conventional rocket engines require vast amounts of liquid oxygen as fuel, the SABRE engine takes advantage of the oxygen in the surrounding atmosphere, which reduces the required oxidizer by over 250 tonnes. Once outside of the atmosphere, the rocket phase requires onboard oxygen. During takeoff and initial ascent the SABRE engine runs in jet engine mode so it can use the oxygen from the air. Until REL’s breakthrough technology, this configuration was not possible. As the air intake speed increases, the air intake temperature also increases. By the time it is travelling at Mach 5.5 the air intake temperature is around 1000 ⁰C. At this temperature conventional jet engines cannot operate—materials begin to fail and the air cannot be effectively compressed. REL’s solution to this problem is to super cool the air from 1000 ⁰C to cryogenic temperatures (-150 ⁰C) in less than a hundredth of a second with a pre-cooler. Flight weight is the point at which a component’s performance justifies its weight. The pre-cooler required the development of a new generation of heat exchangers that can not only transfer 400 MW of heat, but can do it at flight weight (that is, 100X lighter than conventional heat exchangers). This miniaturisation of a heat exchanger can be compared to the miniaturisation of the electronic circuit board to the microchip.

Plans for the Skylon plane are still in their infancy but the technology that provides the incredible thrust to weight ratio required to accelerate the plane to Mach 5.5 inside the atmosphere (over five times the speed of sound and over twice the speed of the world’s fastest air breathing plane, the Blackbird) and on to Mach 25 to break out of the atmosphere is already mature. Whilst conventional rocket engines require vast amounts of liquid oxygen as fuel, the SABRE engine takes advantage of the oxygen in the surrounding atmosphere, which reduces the required oxidizer by over 250 tonnes. Once outside of the atmosphere, the rocket phase requires onboard oxygen. During takeoff and initial ascent the SABRE engine runs in jet engine mode so it can use the oxygen from the air. Until REL’s breakthrough technology, this configuration was not possible. As the air intake speed increases, the air intake temperature also increases. By the time it is travelling at Mach 5.5 the air intake temperature is around 1000 ⁰C. At this temperature conventional jet engines cannot operate—materials begin to fail and the air cannot be effectively compressed. REL’s solution to this problem is to super cool the air from 1000 ⁰C to cryogenic temperatures (-150 ⁰C) in less than a hundredth of a second with a pre-cooler. Flight weight is the point at which a component’s performance justifies its weight. The pre-cooler required the development of a new generation of heat exchangers that can not only transfer 400 MW of heat, but can do it at flight weight (that is, 100X lighter than conventional heat exchangers). This miniaturisation of a heat exchanger can be compared to the miniaturisation of the electronic circuit board to the microchip.

Validating the Enabling Technology

To validate the pre-cooler technology, REL built and tested a representative section of a full-size pre-cooler. The company constructed this test module from about 27 km of 1 mm diameter tubes with wall thickness less than that of a human hair. Within the pre-cooler, the air passes over these tubes and transfers its heat to cooling fluid that runs through the tubes. The construction of this pre-cooler module demonstrated that the precise engineering could be achieved, including the attachment of the 1 mm tubes with over 15,000 precision-brazed joints.

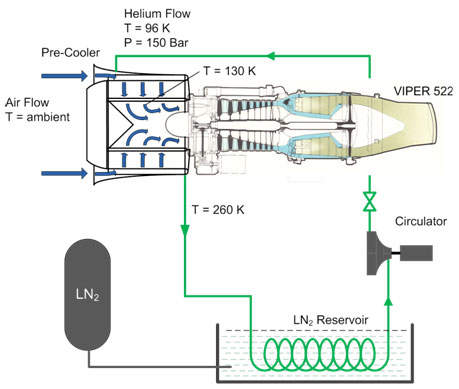

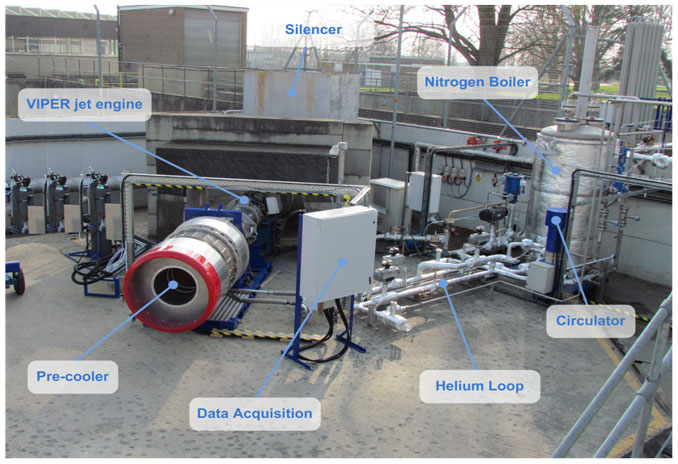

After demonstrating the manufacturing technology, the next task was to prove the pre-cooler was an efficient heat exchanger and was robust enough for its challenging operating environment. This required demonstrating the pre-cooler in actual working air flows and cryogenic conditions. The required air mass flows are immense and cannot be generated with electric fans. Instead of an electric fan, a Viper 522 jet engine pulled the high air flow mass through the pre-cooler. In the actual SABRE engine, liquid hydrogen provides the cooling, but to simplify the test conditions, liquid nitrogen substituted the liquid hydrogen as the cooling source.

On the SABRE engine there are many complexities to pass the liquid hydrogen through the pre-cooler so a secondary cooling circuit of helium exchanges the heat between the precooler and the liquid hydrogen. Similarly, on the test rig a secondary cooling circuit of helium exchanges the heat between the precooler and the liquid nitrogen. Though the test rig only represented a fraction of the SABRE pre-cooler, the heat transferred was such that it would boil over a ton of liquid nitrogen every five minutes.

Validation System Implementation

We instrumented the whole test system using NI LabVIEW system design software and NI CompactDAQ measurement hardware. The modular nature of the NI CompactDAQ platform helped us quickly and easily customise our data acquisition system for the task at hand. We used a combination of analogue and digital modules to take in a range of signals including engine speed, air, and component temperatures, as well as the air pressure and flow throughout the system. The data acquisition system had to handle a wide range of signals, for example temperature varying from

-196 ⁰C to 1000 ⁰C and pressures from vacuum to 250 bar.

For safety reasons, the technicians cannot be in close proximity to the test system during the test. We used flexible NI-DAQmx drivers so that acquisition devices could be used over a variety of communication buses with the same application programming interface. For the main pre-cooler diagnostics, we used a local 8-slot NI cDAQ-9188 chassis communicating via Ethernet. We used a 4-slot NI cDAQ-9174 chassis communicating over USB, located within the control room, to interface with the plant control system.

LabVIEW helped us bring together all the different system components under one application. The NI LabVIEW Datalogging and Supervisory Control Module provided seamless integration with a Mitsubishi PLC, which controlled the system and also helped the development of the SCADA UI. The team took advantage of flexible UI development tools offered by LabVIEW to create a very large user interface, which spanned four monitors and displayed over 150 signals on 28 live charts. The displayed information is logically grouped such that one screen displays pre-cooler data, one displays the helium loop, another displays the frost control, and the fourth displays air diagnostics. Our engineers could monitor a vast amount of information during the test with this array of live charts.

All the data acquired needed extensive analysis and it was important for all the data to be logged to file. In order to achieve the incredibly fast write speeds necessary to capture all the data, we incorporated NI Technical Data Management Streaming (TDMS). We only take advantage of a small fraction of the maximum write speed for TDMS of 400 MB/s, but as we expand to testing larger systems and integrate other technologies, we are comfortable that our software application can scale to fit.

Future of the Project

The European Space Agency has evaluated the SABRE engines pre-cooler heat exchange on behalf of the United Kingdom Space Agency and has given official validation of the test results. Now that the pre-cooler has been successfully validated, we can reconfigure the testbed to test other subassemblies before we bring all the subsystems together into a full-size demonstration SABRE engine to commence ground testing.

With the flexibility of LabVIEW, all the existing components can be reused in the new system and we can rewrite the software to the new requirements. Some of the signals can be reallocated and the system can be enhanced with additional hardware, which saves both time and the cost of buying a new system.

Conclusion

Skylon, with its SABRE engines, is on its route to true 21st century commercially viable access to space. We have successfully demonstrated the key enabling new technology, the pre-cooler, and work is escalating to take the development to the next stages of system integration testing. LabVIEW has been an integral development tool for the pre-cooler testing and will be used for further development test systems.

Find out more here