The first gas company in the U.S., The Gas Light Company of Baltimore, Maryland, founded in 1816, struggled for years with financial and technical problems while operating on a “flat rate” basis. Its growth was slow with the charge for gas service beyond the pocketbook of the majority.

By comparison, the New York Gas Light Company, founded in 1823, prospered and expanded. They had built their system on “the use of gas meters to measure the supply of gas to customers, and a large one to register the quantity made at the station before it is conveyed to the gas meters.

The pattern of operation used by this New York Company was quickly copied by other companies throughout the East Coast, including the Baltimore Company. Seeing the success, New York businessmen formed new gas companies in Albany, Boston, Philadelphia, New York, etc. and the new U.S. gas distribution industry began to flourish.

Since this early beginning, meters have been an important, integral element in every phase of gas industry operations. Various types of meters are used; diaphragm, rotary, turbine, and orifice; each serving a definite purpose and meeting specific requirements.

These four common types of meters can be broken down into two distinct categories: positive displacement and inferential. Diaphragm and rotary meters fall into the positive displacement category because they have well- defined measurement compartments that alternately fill and empty as the meter rotates. By knowing the volume displaced in each meter revolution and by applying the proper gear ratio, the meter will read directly in cubic feet or cubic meters.

Turbine and orifice meters, on the other hand, have no measurement compartments to trap and then release the gas. These meters are inferential meters in that the volume passing through them is “inferred” by observing or measuring some physical characteristic.

WORKING OF GAS METERING

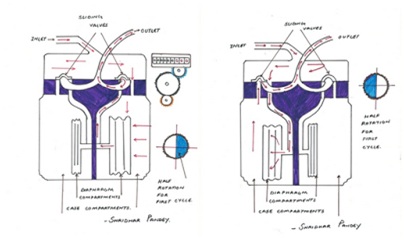

Above each diaphragm is a “D” shaped valve (See Figure 1.).Under the valve are three port openings that direct the flow of gas in and out of the case and diaphragm compartments. As the diaphragm expands, it forces the gas in the case compartment up through the case port.

Above each diaphragm is a “D” shaped valve (See Figure 1.).Under the valve are three port openings that direct the flow of gas in and out of the case and diaphragm compartments. As the diaphragm expands, it forces the gas in the case compartment up through the case port.

The valve directs the flow of gas into the centre port that leads to the meter outlet. A similar process occurs when the diaphragm contracts. The stroke of the diaphragm is controlled by linkage in the upper port of the meter and a rod (flag rod) that extends down into the diaphragm compartment.

The tangent link, as it is called, is attacked to the top of the meter crank and is adjustable in length. Increasing the tangent length increases the diaphragms’ stroke which increases the meter proof and vice versa (See Figure 2.)

The crank makes a certain number of turns per cubic cubic foot and transmits this motion to the front counter (index) by means of an axle shaft driven by a worn and wheel. The crank also drives the sliding valves, which are timed to the motion of the diaphragm.

PROBLEM DESCRIPTION

- Technical loss due to improper and inefficient metering.

- High Operational cost.

- Error due to manual reading.

- Security Risks due to manual reading.

- Inability to adapt to distributed energy resources and energy retail market.

- Poor customer experience arises from manual meter reading and billing.

- No scope for HAN and Multi utility metering.

REQUIREMENT OF AMI FOR GAS METERS

The Primary Objective of this project includes:

- AMR(Automatic meter reading)

- Home Area Networking

- Network Management of Data concentrator and meters

- Monitoring and Configuration of Field Devices.

- Interfacing a meter data BASE TO VARIOUS Utility applications such as customer care, Billing and Quality Analysis.

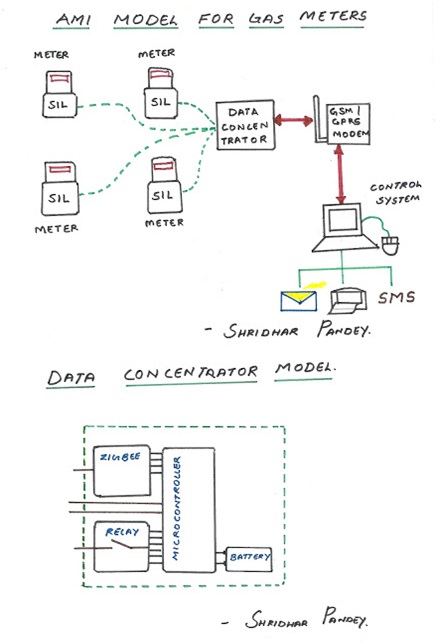

IMPLEMENTATION OF AMI FOR GAS METERS

FEATURES OF AMI

- Remote Disconnect/Reconnect

- Flexible Two-Way Data Retrieval and Scheduled Data Collection

- Users can execute all appropriate functionality as an on-demand basis.

- Automated Interval Data Usage Retrieval

- Real-Time Interval Reads

- Automated Register, Self-Read and TOU Retrieval

- Real-Time Meter Event and Alarm Retrieval

- Service Diagnostic and Tamper Detection Alerts

- Tilt Detection

- Meter Clock Synchronization

- Smart Meter Status Display

- Automated Meter Registration

- Secure and Encrypted Data Transmissions

- Bi-Directional Metering

APPLICATIONS OF AMI FOR GAS METERING

- More accurate settlement and billing

- Smart homes

- Modelling and forecasting

- Services for monitoring and improving energy efficiency of end use and distributes generation, customer information feedback

- Customer service

- Prepayment

- Meter management

- Connect, disconnect

- Fraud detection

- Tariff settling

- Preventive maintenance and Analysis of Failures

Contact for more details:

Shridhar Pandey,

Ramway Technology CO. Ltd., China

Contact Number: +91-8000402389

Email id: Shridhar.pandey@ramwaycn.com