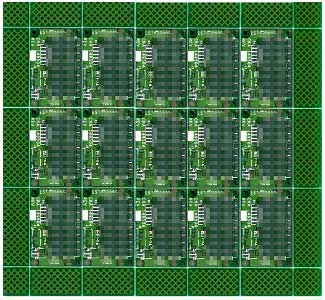

Most PCBs are individually routed — meaning they’re not panelized. That doesn’t mean that, sometimes, sending them to a PCB assembler in a panel isn’t a good idea or even required. Generally assemblers don’t require panels — sometimes called a pallet — but there are some cases when they do.

Most PCBs are individually routed — meaning they’re not panelized. That doesn’t mean that, sometimes, sending them to a PCB assembler in a panel isn’t a good idea or even required. Generally assemblers don’t require panels — sometimes called a pallet — but there are some cases when they do.

If the individual PC board, destined for Full Proto service, is smaller than 0.75″ x 0.75″, it needs to be panelized. If a PC board needing Short Run production service is less than 16 square inches, it needs to be in a panel of at least 16 square inches to qualify for Short Run.

Why else might you want to panelize PC boards?

- Protection — If you’ve got a lot of small boards, it’s easier to handle and protect then when they’re in a panel. A few panels can be more safely packed coming and going from your company to an assembler.

- Safety — You may be able to get the boards through a factory faster. If you have a really large number and need them super fast, panelizing them may enable that fast turn. With a lot of boards, sometimes it simply isn’t physically possible to put them all on the machine, run them and take them off, in a short turn time. Panelize them and the machine will be running longer for each board change, which reduces the total run time.

- Cost — It may also cost you less. If you use leadless parts like BGAs, QFNs or LGAs, you can usually reduce your cost a bit by panelizing the boards. Leadless parts cost a little extra because of the X-Ray test needed, but the extra handling is mostly per board, rather than per part. One panel of 10 boards with 10 BGA, in total, will cost a little less than 10 individual boards with one BGA each.

Duane Benson is the Chief Technology Champion at Screaming Circuits, a prototype PCB assembly electronic manufacturing company in Canby, Oregon.